Prof. Armin Schnettler from Siemens' central research department and Prof. Achim Kampker, Managing Director of StreetScooter, agreed today to equip an electric car from StreetScooter with an innovative electronic and software architecture by end of 2014.

Siemens is equipping electric cars with completely redesigned information and communications technology (ICT). Basically, the idea is to control a variety of vehicle functions on a uniform, centralized computer platform instead of providing every system with its own hardware and software as today. The aim is to simplify the complicated interplay of the many assistance, safety, and infotainment systems. In addition, separating the software from the technology on which it runs facilitates retrofitting new features. In the same way that apps use smartphones' existing technology, such as GPS or cameras for their own purposes, integrated standard components such as proximity sensors, control units, and display elements could be used for new functions in automobiles. The all-new ICT concept was developed by Siemens' global Corporate Technology (CT) department and its partners in the government-funded RACE project.

The new ICT architecture will simplify the introduction of new functions in electric cars. It will also make it more cost-effective and enable the features to be installed in small batches of vehicles. To test these possibilities in real-life, researchers at CT will introduce the new technology into a StreetScooter electric delivery vehicle by December 2014. In addition to communications networks and software, the vehicle will receive a standardized computer platform developed by CT. Siemens will also provide the company StreetScooter with a software development environment that will allow it to incorporate new functions into the system and integrate them into the car. StreetScooter GmbH develops and produces electric vehicles for short runs. It is currently focusing on creating customized solutions for transport vehicles used for parcel delivery services or local public transportation, for example.

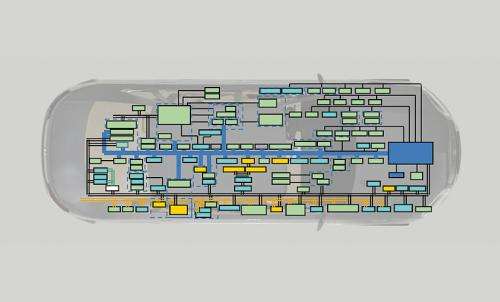

The RACE project has developed an electronics and software architecture for electric vehicles that represents a paradigm shift for automobile manufacturing. Previously, automotive systems such as anti-lock braking systems, parking aids or air-conditioning controls had all been independent, stand-alone units. A mid-range car contains more than 70 of these control units from a variety of suppliers. Ensuring they all interact smoothly with one another is therefore a complicated process. For the RACE project, the researchers at Siemens CT not only developed the central computer platform and the communications technology, but also the software that brings all of the different systems together and ensures their failsafe operation. This also simplifies the integration of safety-related systems, such as those needed for autonomous driving.

Today a mid-range vehicle may contain over 70 different control systems that are all networked with one another. Added to this are thousands of sub-functions that run on these control systems and exchange data. In the RACE project, by contrast, cars are controlled by a centralized computing architecture. The approach is similar to the fly-by-wire systems and other technologies used in today's airplanes. Such a uniform software architecture would enable developers to create new functions quickly and easily. In addition, software functions could be pushed out to vehicles in the same way that they are to smart phones.

Provided by Siemens