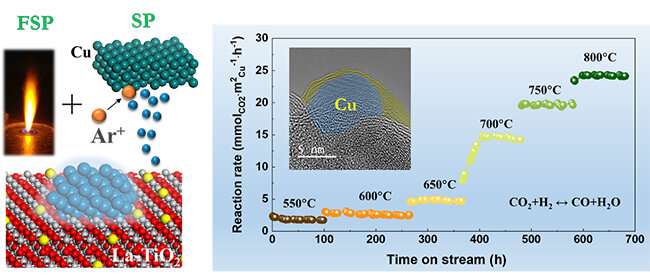

Ultra-stable Cu/LaTiO2 heterogeneous catalyst at 800 degrees Celsius. Credit: Yu Jiafeng

The development of Cu-based catalysts is limited due to their poor thermal stability caused by the low Tammann temperature of Cu.

Recently, a research group led by Prof. Yu Jiafeng and Prof. Sun Jian from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) constructed an ultra-highly stable Cu-based heterogeneous catalyst at high temperatures by constructing classical strong metal-support interactions (SMSIs).

This study was published in Nature Communications on Dec. 10. Prof. Noritatsu Tsubaki from Japan's Toyama University and Prof. Liu Yuefeng from DICP were also involved in this study.

The researchers combined two unique technologies, magnetron sputtering (SP) and flame spray pyrolysis (FSP), to reconstruct the electronic structure of metallic Cu and the reducibility of the TiO2 support, respectively.

They created the classic SMSI on non-noble metal Cu-based catalyst at mild reduction temperatures for the first time, and realized controllable preparation of ultra-highly stable Cu-based catalyst. This catalyst exhibited ultra-stable performance for more than 500 hours at 600 degrees Celsius. The sintering of Cu nanoparticles was effectively suppressed even at 800 degrees Celsius.

Moreover, the strength of SMSI could be effectively controlled not only by reducing temperatures as before but also by tailor-made Cu via sputtering power regulation or decorated supports for rational catalyst design on demands.

"We expect that our new findings will serve as a general guide to design a highly stable heterogeneous catalyst at a wider range of temperatures," said Prof. Sun.

More information: Jiafeng Yu et al, Ultra-high thermal stability of sputtering reconstructed Cu-based catalysts, Nature Communications (2021). DOI: 10.1038/s41467-021-27557-1

Journal information: Nature Communications

Provided by Chinese Academy of Sciences