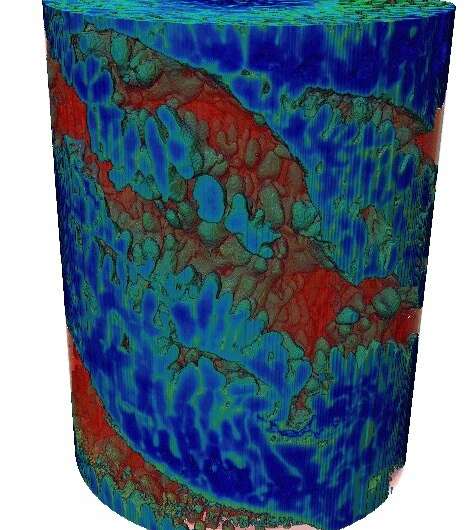

Under the influence of magnetic stirring, helical screw-like crystals form in molten alloy. Credit: Dr Biao Cai

An innovative method for aluminum recycling has been boosted by research showing the microscopic changes that take place when molten alloys cool.

Researcher Dr. Biao Cai from the University of Birmingham's School of Metallurgy and Materials used sophisticated high-speed X-ray imaging to record the formation of micro-crystals as alloys cool and solidify, under a magnetic field.

A mathematical model was developed by his collaborator Dr. Andrew Kao from the University of Greenwich to predict whether micro-crystals would form, and what shape they would have.

The model predicted that that helical 'screw-like' crystals would form under the influence of strong magnetic stirring, and the high-speed X-ray confirmed that this occurred.

Although these elegant crystals are just micro-meters wide (ten times smaller than a human hair), they have implications for industrial-scale processes.

Biao explains: "These microscopic crystals ultimately determine the physical properties of the alloy. To be able to adjust their shape, structure and direction of growth will enable us to perfect processes for both manufacturing and recycling of metals and alloys".

Biao has already invented technique to improve aluminum recycling by removing iron. Iron is a detrimental element that can make aluminum brittle, and limit its use in premium applications such as aircraft.

Existing methods for removing iron during recycling are either expensive or inefficient, but Biao's simple, inexpensive technique uses magnets and a temperature gradient to remove iron contamination.

More information: B. Cai et al. Revealing the mechanisms by which magneto-hydrodynamics disrupts solidification microstructures, Acta Materialia (2020). DOI: 10.1016/j.actamat.2020.06.041

Provided by University of Birmingham