This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Scientists simulate magnetization reversal of Nd-Fe-B magnets using large-scale finite element models

NIMS has succeeded in simulating the magnetization reversal of Nd-Fe-B magnets using large-scale finite element models constructed based on tomographic data obtained by electron microscopy.

Such simulations have shed light on microstructural features that hinder the coercivity, which quantifies a magnet's resistance to demagnetization in opposing magnetic fields. New tomography-based models are expected to guide toward the development of sustainable permanent magnets with ultimate performance.

Green power generation, electric transportation, and other high-tech industries rely heavily on high-performance permanent magnets, among which the Nd-Fe-B magnets are the strongest and most in demand. The coercivity of industrial Nd-Fe-B magnets is far below its physical limit up to now. To resolve this issue, micromagnetic simulations on realistic models of the magnets can be employed.

A new approach to reconstruct the real microstructure of ultrafine-grained Nd-Fe-B magnets in large-scale models is proposed in this research, now published in the journal npj Computational Materials.

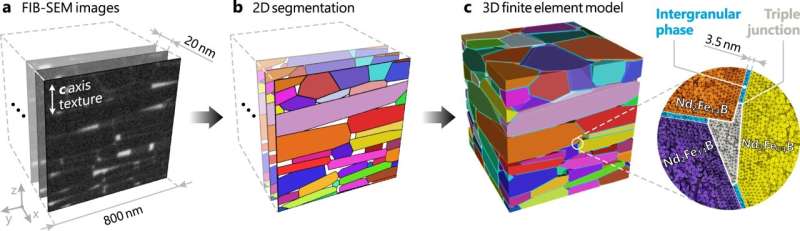

Specifically, the tomographic data from a series of 2D images obtained by scanning electron microscopy (SEM) in combination with consistent focused ion beam (FIB) polishing can be converted into a high-quality 3D finite element model.

This tomography-based approach is universal and can be applied to other polycrystalline materials addressing a wide range of materials science problems.

Micromagnetic simulations on the tomography-based models reproduced the coercivity of ultrafine-grained Nd-Fe-B magnets and explained its mechanism. The microstructural features relevant to the coercivity and nucleation of magnetization reversal were revealed.

Thus, the developed model can be considered as a digital twin of Nd-Fe-B magnets—a virtual representation of an object designed to reflect its physics accurately.

The proposed digital twins of the Nd-Fe-B magnets are precise enough to reproduce both the microstructure and magnetic properties that can be implemented for the inverse problem in designing on-demand high-performance permanent magnets.

For instance, when researchers input the magnetic properties required for a specific application (e.g., traction or variable magnetic force motor), a data-driven research pipeline with integrated digital twins will be able to propose the optimal composition, processing conditions, and microstructure of the magnet for that application, significantly reducing development time.

More information: Anton Bolyachkin et al, Tomography-based digital twin of Nd-Fe-B permanent magnets, npj Computational Materials (2024). DOI: 10.1038/s41524-024-01218-5

Provided by National Institute for Materials Science