Development of new magnet that reduces use of rare-earth element by 30%

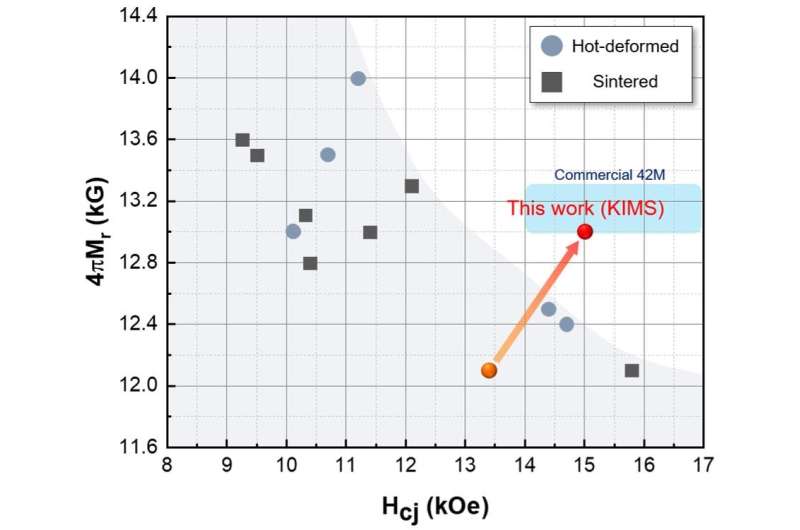

A research team led by Dr. Jung-Goo Lee and Dr. Tae-Hoon Kim of the Department of Magnetic Materials in the Powder Materials Division at the Korea Institute of Materials Science (KIMS), a government-funded research institute under the Ministry of Science and ICT, succeeded in developing rare-earth-saving permanent magnets that can replace the 42M-graded commercial magnets while reducing the amount of neodymium (Nd), an expensive rare-earth material, by about 30%. The technology achieved the commercial level of performance currently used in the industry, even though the amount of high-priced rare-earth resources is reduced.

Neodymium is an expensive and unstably supplied material, but it is essential for manufacturing rare-earth permanent magnets. In order to develop an Nd-reduced permanent magnet, the content of cerium (Ce), an inexpensive element, was increased, instead of reducing the content of Nd. Until now, with the increased content of Ce, deterioration of the magnetic properties was inevitable. The research team focused on clarifying the reason for and mechanism of the deterioration of the magnetic properties caused by the increased Ce content, and they successfully solved the problem of rare-earth-reduced permanent magnets by controlling the atomic-scale microstructure.

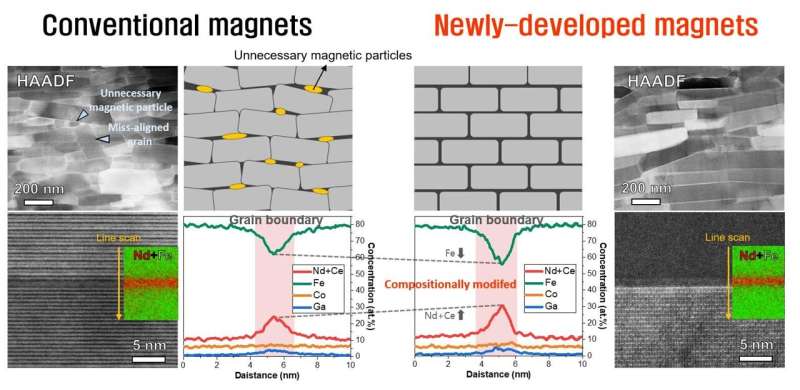

The researchers discovered that unnecessary magnetic particles were formed during the manufacturing process, the underlying reason for the deterioration of the magnetic and microstructural properties of the magnets. They modified the microstructure and enhanced the magnetic properties by preventing the diffusion of atoms so that the formation of unnecessary magnetic particles is suppressed.

The research team applied the melt-spinning method and the hot-deformation method, which have very fast cooling rates compared to the conventional process, to the process of fabricating rare-earth-reduced precursors and final bulk magnets, respectively. As a result, they succeeded in optimizing the microstructure of the magnets by suppressing the formation of unnecessary magnetic particles. In addition, they were able to simultaneously improve the residual magnetization and coercive force, which are the main properties of permanent magnets.

The domestic market for rare-earth permanent magnets for high-efficiency motors was worth $186 billion per year in 2021, and Korea depends on imports of the material. Considering current issues such as China's weaponization of rare-earth resources, Japan's export restrictions on magnetic materials, and global carbon neutrality, localization of rare-earth permanent magnet materials is necessary for Korea. When this technology is commercialized, it can be used in high value-added industries such as electric vehicles, drones, flying cars and electric ships that require high-efficiency motors.

Dr. Tae-Hoon Kim, a senior researcher at KIMS, who led the research team, said, "When the technology is commercialized, it will simultaneously solve the resource problems and material, parts, and equipment issues in the domestic rare-earth permanent magnet markets. This is only the beginning. With further research in the future, we will spare no effort to lead the development of the domestic rare earth permanent magnet industry."

The research results were published in Scripta Materialia on March 17.

More information: Ga-Yeong Kim et al, High-performance Ce-substituted (Nd0.7Ce0.3)-Fe-B hot-deformed magnets fabricated from amorphous melt-spun powders, Scripta Materialia (2022). DOI: 10.1016/j.scriptamat.2022.114676

Journal information: Scripta Materialia

Provided by National Research Council of Science & Technology