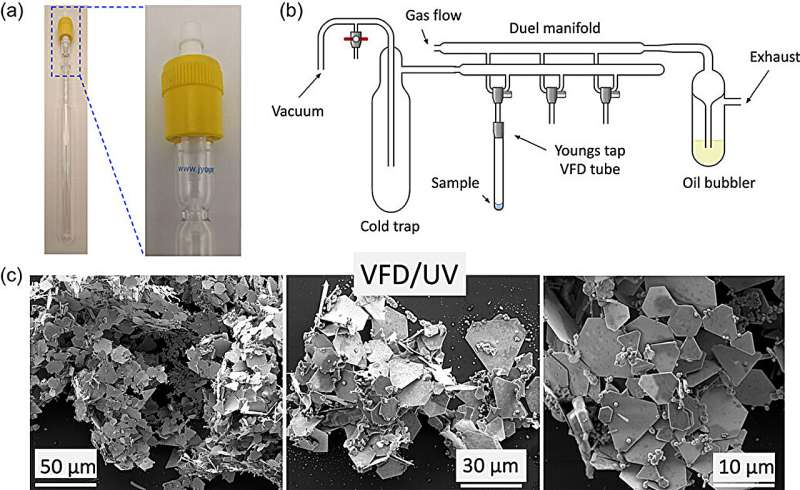

a) Photograph of a 20 mm OD quartz tube fit with a Young's tap. b) Schlenk line apparatus for preparing nitrogen atmosphere in a sealed tube. c) SEM images of gold nanosheets formed after 60 min VFD processing with ω = 5 k rpm, θ. Credit: Small Science (2024). DOI: 10.1002/smsc.202300312

In a surprise discovery, Flinders University nanotechnology researchers have produced a range of different types of gold nanoparticles by adjusting water flow in the novel vortex fluidic device—without the need for toxic chemicals. The article, "Nanogold Foundry Involving High-Shear-Mediated Photocontact Electrification in Water," has been published in Small Science.

The green chemistry lab work on nano gold formation also led to the discovery of a contact electrification reaction in water in the device—which resulted in the generation of hydrogen and hydrogen peroxide.

In their study, Australian and overseas scientists collaborated on the developing size and form of gold nanoparticles from various VFD processing parameters and concentrations of gold chloride solution.

"Through this research, we have discovered a new phenomenon in the vortex fluidic device. The photo-contact electrification process at the solid-liquid interface which could be used in other chemical and biological reactions," says Flinders Ph.D. Badriah Mazen Alotaibi, who led the study.

"We also have achieved synthesis of pure, pristine gold nanoparticles in water in the VFD, without the use of chemicals commonly used—and thus minimizing waste," says Mr. Alotaibi.

"This method is significant for the formation of nanomaterials in general because it is a green process, quick, scalable and yields nanoparticles with new properties."

Gold nanoparticles' size and shape are critical for a range of applications—from drug delivery to catalysis, sensing and electronics—due to their physical, chemical and optical properties.

The vortex fluidic device, devised a decade ago by senior author Flinders University Professor Colin Raston, is a rapidly rotating tube open at one end with liquids delivered through jet feeds. Different rotational speeds and external application of light in the device can be used to synthesize particles to specification.

"Researchers around the world are now finding the continuous flow, thin film fluidic device useful in exploring and optimizing more sustainable nano-scale processing techniques," says Professor Raston.

"In this latest experiment, we hypothesize that the high shear regimes of the VFD led to the quantum mechanical effect known as contact electrification, which is another exciting development."

Professor Raston says this discovery "is a paradigm shift in how to make materials in a controlled way using water, with no other chemicals required, which contributes to a more sustainable future."

More information: Badriah M. Alotaibi et al, Nanogold Foundry Involving High‐Shear‐Mediated Photocontact Electrification in Water, Small Science (2024). DOI: 10.1002/smsc.202300312

Provided by Flinders University