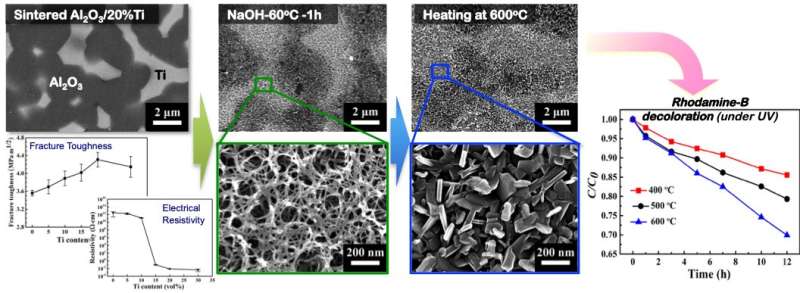

(Upper left) This is a structure of Ti-dispersed AI2O3 composites(Lower left) Ti content dependency of fracture roughness and electrical resistivity (Middle) Nanostructure of the surface of AI2O3 composites produced via chemical and heat treatments(Right) Discolored by the photocatalytic activity of AI2O3 composites after chemical and heat treatments. Credit: Osaka University

Researchers at Osaka University have produced composites consisting of alumina (AI2O3) ceramics and titanium (Ti), namely AI2O3/Ti composites. They designed a percolation structure for forming a continuous conduction pathway by dispersing fine-sized Ti particles into an AI2O3 matrix, optimizing the particle size of metallic Ti powder and sintering processes. They improved fracture toughness and electrical conductivity of AI2O3/Ti composites while simultaneously giving them photocatalytic ability through chemical and/or thermal treatment. (Figure 1)

Various types of metal-ceramic composites have been researched and developed, but their combination and fine structures were limited. In particular, the combination of ceramics such as alumina used as matrices and titanium, a biocompatible metal, has a problem in that the structure of composites is not uniform because of the high reactivity of titanium (oxidation happens and chemical compounds are produced) and the large particle size of commercially-available Ti powder (several tens of micrometers). Thus, it was difficult to produce composites that have advantages of both ceramics and metal: that is, composites in which metallic Ti powder is homogeneously dispersed in the matrix and has excellent mechanical properties.

The group prepared ball-milled titanium hydride (TiH2) fine powder mixed with alumina powder, producing AI2O3/Ti composites using a method based on the in situ decomposition of TiH2 to Ti and simultaneous sintering with Al2IO3, which process inhibited AI2O3 dissolution into Ti by diffusion through interfacial reaction between AI2O3 and Ti during sintering. As a result, they minimized reactivity of Ti and AI2O3 to disperse significantly finer and more homogeneous Ti (compared to those produced with conventional methods) in AI2O3, realizing composites with a percolation structure by controlling the content of added Ti.

In this way, the group improved fracture toughness of inherently brittle AI2O3 through dispersion of fine Ti particles into AI2O3 and, due to percolation of metallic Ti particles, contributing electrical conductivity to insulator ceramics AI2O3. They also demonstrated that AI2O3 ceramics could be machined by electrical discharge machining like metals. (Usually, ceramics are not electrically conductive.) In addition, they formed a nano-porous- or nanorod- structured titania layer on the surface of the composite by selectively oxidizing Ti via NaOH treatment and/or heat treatment. Through this, they demonstrated that the photocatalytic ability to break down organic substances could also simultaneously be given to AI2O3/Ti composites.

Group leader Tohru Sekino says, "AI2O3/Ti composites will be used as ceramic matrix composites that have excellent mechanical properties and can be machined by electrical discharge machining. They will also be used for industrial products and biomaterials as new multi-functional composites that have an active surface layer with antibacterial properties and a photocatalytic ability to break down pollutants."

More information: Shengfang SHI et al, Surface-morphology modification of ceramic-based composites for photocatalytic activity via simple chemical and heat treatments, Journal of the Ceramic Society of Japan (2018). DOI: 10.2109/jcersj2.18119

Provided by Osaka University