RemLife is an innovative software tool developed at ANSTO for use at power stations to help maintain plant components and improve the efficiency of operations—including conventional power stations, combined cycle heat steam recovery boilers and nuclear power stations.

Materials that are subjected to extreme pressure and temperatures undergo changes that must be monitored.

RemLife calculates the damage that power station components sustain during operating cycles and can be used to predict how long the plant can operate safely.

"It allows a quick and accurate assessment of component damage based on operating conditions without actually testing it in real life. Using RemLife, power stations are able to optimise operations, reduce downtime, and reduce carbon emissions," said Materials Engineer Dr Warwick Payten, who was a key contributor to the development of the software.

"Almost all large thermal and combined cycle power stations in Australia use RemLife to manage their assets," said Payten.

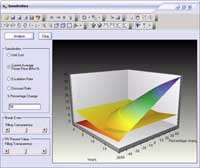

RemLife uses a combination of methodologies to perform quick and accurate analyses of the effects of high temperature and high pressure on industrial plant components. Additionally, it can be used to compare the economic benefits of specific cycling regimes.

Engineers can determine which components are at risk due to their operational history and plan future operating regimes.

"It enables power plant managers to quickly screen a large number of components to see which ones may be at risk due to planned operations and gauge the overall operational state of the plant," said Payten.

"Rather than spending a week assessing a single component, that assessment can be carried out in minutes," said Payten.

Extending the life of components can deliver multibillion dollar savings through optimisation of existing assets and accurate energy forecasting, which avoids the need for investments in new infrastructure.

"The software calculates both base rupture damage as well as cyclic damage due to start-ups and shutdowns," said Dr Warwick Payten.

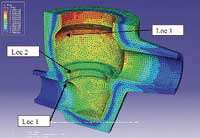

"It bridges the gap between 'back-of the envelope' calculations for base rupture and fully detailed finite-element analysis for creep-rupture and combined creep-fatigue analysis," he said.

Proof of concept for the software occurred in 2005 and the first version was released in March 2006. Later versions were released in 2007 and 2009 in association with 10 power stations. RemLife became a fully commercial product in 2010.

Payten said the code was rewritten in 2012. Further releases occurred in the period to 2015, when the stand alone code was migrated to a fully integrated cloud-based application.

ALS Global, an Australian-owned multinational company and a global leader in analytical and technical services markets, acquired the RemLife technology from ANSTO in 2015 to drive international expansion in the provision of technical services to the global power generating industry.

ANSTO retains commercial rights for its use in nuclear industries.

"The acquisition is an endorsement of the quality of the research and recognises ANSTO as a knowledge centre for this methodology," said Payten.

Payten explained that the need for the technique came about because many steam driven power plants have changed the way in which electricity is generated and used. They were responding to changes in demand and competition from alternative energy suppliers.

Aging power plants, designed to produce electricity at a constant rate (baseload supply), are now being operated in a high-cycling mode. This places additional stress on plant infrastructure beyond what was originally intended when these plants were designed and built.

"RemLife enables the modelling of creep-fatigue stress on aging infrastructure and determining the most efficient and effective ways to maintain and operate a plant in response to power grid fluctuations," said Payten

Following the British Energy-R5-R6 Assessment Code standard, RemLife calculates creep fatigue using time fraction, ductility exhaustion and strain energy density exhaustion as well as complying with international standards for the calculation of primary and secondary stresses.

The RemLife simulation software uses analytical expressions to determine the loading history, the cyclic stress-strain deformation loops; calculate metastable thermal stresses, total creep fatigue damage and the economic consequences of cyclic damage; assess whether crack initiation will occur and obtain creep-fatigues endurances to complement an inspection of physical assets. An extensive materials library has been built into the package.

"The ability to break down complex plant into simple components enables RemLife to be utilised effectively in various other process industries where creep, low cycle fatigue and creep-fatigue may occur," said Payten.