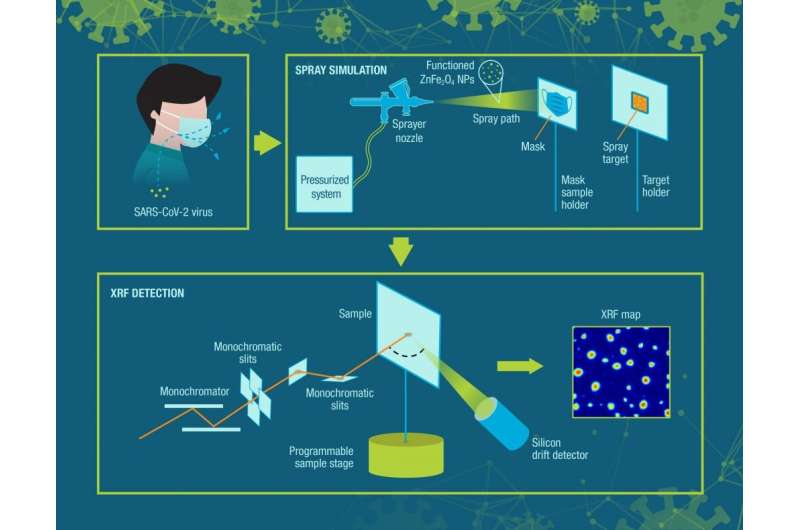

This visual of the mask material testing shows the spray simulation process (top graphic), and implementation of x-ray fluorescence spectroscopy to further measure nanoparticle spread and reach (bottom graphic). Credit: Yelena Belyavina

In a study that used inorganic, physical and analytical chemistry to mimic respiratory droplets that can carry viruses, researchers demonstrated a mechanism that enables multiple mask materials to be protective. Led by Stony Brook University Professor Amy Marschilok, Ph.D., the study findings suggest that adsorptivity of mask materials is an important feature in providing protection from viruses such as SARS-CoV-2. The paper is published in Applied Materials & Interfaces.

Studies evaluating dry measurements of particles to test mask breakthrough have been conducted during the 2020-21 pandemic. In contrast, researchers in this investigation used a novel method that involved creating a virus nanoparticle mimic, using functionalized nanoparticles suspended in artificial saliva, then spraying the suspension and providing scientists with a unique wet characterization approach to compare the effectiveness of potential mask materials. Thus, rather than viewing the mask as a simple screen, the study tests the adsorptive properties of the mask materials for trapping virus in saliva droplets.

"We recognized the precious nature of the N95 respirators, and therefore decided to compare mask materials that are broadly available and represented a range of technology and manufacturing readiness using the evaluation methodology that we developed," says Marschilok, Co-Director of the Institute for Electrochemically Stored Energy, Associate Professor in the Department of Chemistry and Adjunct Faculty Member, Department of Materials Science and Chemical Engineering. She also has a joint appointment with the U.S. Department of Energy's (DOE) Brookhaven National Laboratory (BNL), of which Stony Brook is part of the management team.

The masks ranged from a commercialized N95 product to a commercially available mask material, and a potential future mask material prepared by Oak Ridge National Laboratory's Carbon Fiber Technology Facility. Each material was characterized using a variety of methods, including scanning electron microscopy and X-ray photoelectron spectroscopy at BNL's Center for Functional Nanomaterials (CFN).

Wetting properties of the mask materials were quantified by measurements of the contact angle with an artificial saliva. The surface functionalized metal oxide nanoparticle suspension in artificial saliva was sprayed with an airbrush device through the mask material onto a target. The amount of suspension reaching the target was measured using X-ray fluorescence spectroscopy at BNL's National Synchrotron Light Source-II (NSLS-II).

"Our goal was to develop new approaches to characterize mask materials, investigate the adsorptive properties of the mask and consider dispersion of droplets containing the virus. The mechanism investigated adsorbing or trapping the suspended virus mimic rather than blocking it," summarizes Marschilok.

Marschilok and colleagues found that multiple types of mask materials functioned effectively under the test conditions. When the researchers conducted the same experiments to a target without the use of mask protection even at longer distances, much less protection occurred from the viral particles than in the presence of mask materials—a result which further points toward the protective value of masks against virus exposure.

The authors say further investigation is necessary to determine the stability of mask materials over time and extended use as a protection against viral particles.

More information: Chavis A. Stackhouse et al, Characterization of Materials Used as Face Coverings for Respiratory Protection, ACS Applied Materials & Interfaces (2021). DOI: 10.1021/acsami.1c11200

Journal information: ACS Applied Materials and Interfaces

Provided by Stony Brook University