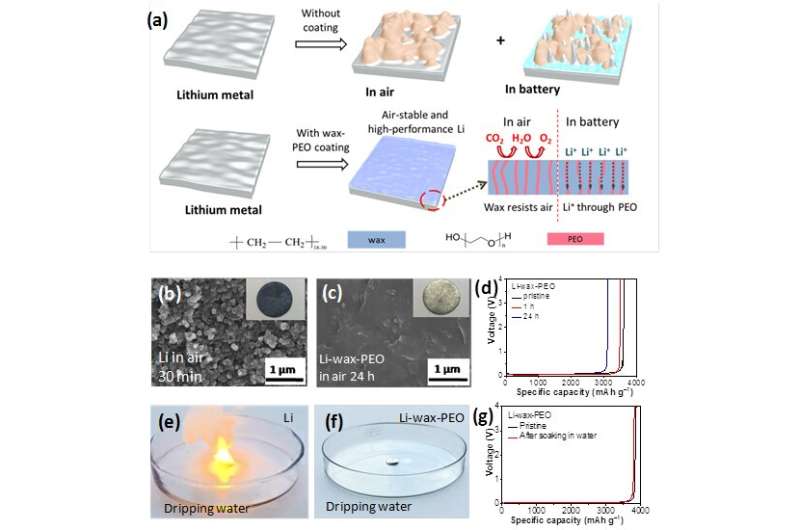

Diagram of the Li-wax-PEO and its stability in the air and water. Credit: Science China Press

Lithium metal anode offers a promising pathway to upgrade the energy density of lithium ion batteries for its high specific capacity (3800 mAh g-1) and low voltage (-3.04 V vs. Li/Li+). But the safety issues caused by dendrite growth and instability in air caused by its high chemical activity limit its large-scale use as an electrode material. Lithium metal is highly sensitive to moisture and oxidative components in the air, leading to the generation of insulating products like lithium hydroxides on its surface and the resultant deterioration of the electrochemical performance. Moreover, when lithium contacts water, combustion and explosion can occur due to the production of hydrogen and heat. The sensitivity of lithium metal therefore necessitates demanding requirements for the transport, storage and process of lithium metal anode. It is hence highly desirable to develop an air-stable and waterproof lithium metal anode for potential use in the future.

In the electronics field, packaging technologies protect electronic components from physical damage and corrosion in humid air and water with a coating, which provides design impetus for the protection of lithium metal. Recently, a research team led by Prof. Quan-Hong Yang in Tianjin University and Prof. Wei Lv in Tsinghua University developed a wax-PEO coating for lithium metal surfaces utilizing a simple dip coating method to realize an air-stable and waterproof lithium metal anode. Wax as a commonly-used inert sealing material is easily coated on the surface of lithium metal. This wax-based composite coating prevents adverse reactions of lithium metal in air and water. In batteries, the coating retards the etching of electrolyte to the surface of lithium metal anodes while the homogeneously distributed PEO guarantees uniform lithium ion conduction at the interface and inhibits the growth of lithium dendrites.

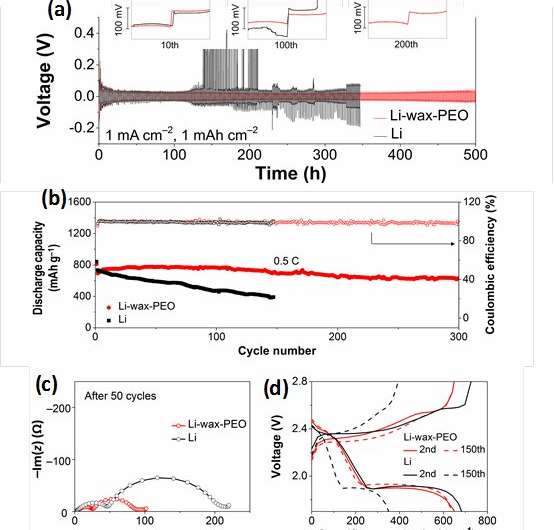

Under the protection of wax-PEO coating, lithium surfaces remain unchanged in air with high relative humidity of 70% for 24 hours, and high capacity retention of 85% is achieved. Even contacting lithium with water immediately, no combustion or capacity decay occurred. The coated lithium metal anode remains stable for as long as 500 hours in symmetric cells, and lithium sulfur batteries assembled with the coated lithium metal anode show a low capacity decay rate of 0.075% per cycle for 300 cycles. This work demonstrates an efficient packaging technology for air-stable and waterproof lithium metal anodes. It is also easily scalable and applicable to other sensitive electrode materials.

Electrochemical performances of Li-wax-PEO and Li in symmetric cells and lithium sulfur batteries. Credit: Science China Press

More information: Yunbo Zhang et al, An air-stable and waterproof lithium metal anode enabled by wax composite packaging, Science Bulletin (2019). DOI: 10.1016/j.scib.2019.05.025

Provided by Science China Press