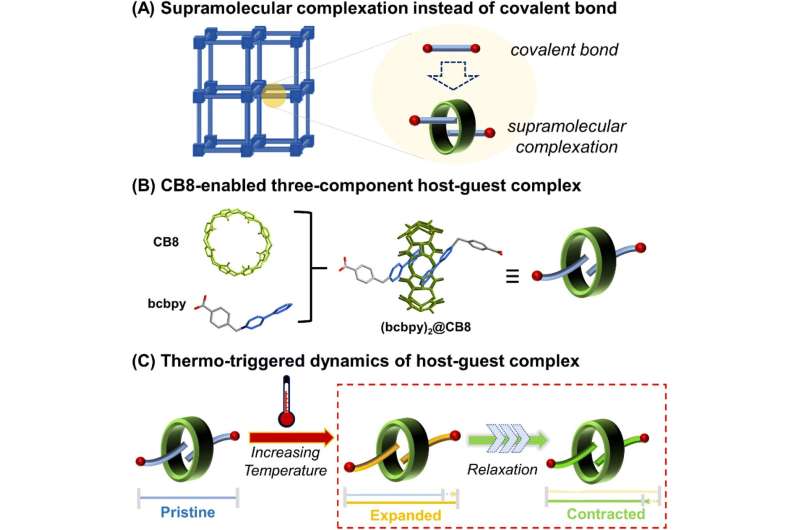

A macrocyclic CB8 three-component host–guest supramolecular complex as a flexible linkage for the development of NTE materials: (A) replacement of covalent bonds with supramolecular complexes in MOFs to produce metal–organic polythreading frameworks; (B) construction of a three-component host–guest complex, (bcbpy)2@CB8; and (C) thermally driven expansion and relaxation-induced contraction of the flexible host–guest complex (bcbpy)2@CB8. Credit: Chemical Science (2023). DOI: 10.1039/D3SC01343J

A team of nuclear chemists at the Chinese Academy of Sciences, working with a colleague from Changzhou University, has discovered a unique relaxation mechanism in a lattice-based material they built that had negative thermal expansion properties. In their study, reported in the journal Chemical Science, the group built latticed-based materials and observed their properties as they were heated.

Most materials expand when heated, which can be a problem in many applications. Expansion in electronic devices, for example, can lead to product failure. However, there are some materials that actually contract when heated. Such materials have what are known as negative thermal expansion (NTE) properties.

A material that has both positive and negative expansion could conceivably result in net zero change, thereby preserving the integrity of its environment. In this new effort, the research team set out to create an NTE material with a controllable level of shrinkage during heating for use with controllable positive thermal expansion materials.

The material created by the team involved the construction of tiny, cage-like structures that shrink a certain amount when exposed to a certain temperature. The shrinking occurs due to spring-like properties of the cages. They were made by introducing organic linkers into a skeleton made of a metal-organic rotaxane. The team calls the resulting material U3(bcbpy)3(CB8). They note that their approach is different from conventional hinging models that shrink due to vibration of atoms.

Testing showed that the material worked in stepwise fashion—heating led to a certain amount of shrinking, which would hold steady. More heat then led to another level of shrinking, demonstrating a degree of control over the process.

But the team also found a unique relaxation mechanism that involved a contraction of the negative thermal expansion that corresponded with a given recovery stage in the material. The researchers suggest the material could have applications where size and shape control in response to heat are needed. They note that the use of uranium may restrict such use, however.

More information: Qiu-Yan Jin et al, Colossal negative thermal expansion in a cucurbit[8]uril-enabled uranyl-organic polythreading framework via thermally induced relaxation, Chemical Science (2023). DOI: 10.1039/D3SC01343J

Journal information: Chemical Science

© 2023 Science X Network