Northwestern University researchers have developed a family of soft materials that imitates living creatures.

When hit with light, the film-thin materials come alive—bending, rotating and even crawling on surfaces.

Called "robotic soft matter by the Northwestern team," the materials move without complex hardware, hydraulics or electricity. The researchers believe the lifelike materials could carry out many tasks, with potential applications in energy, environmental remediation and advanced medicine.

"We live in an era in which increasingly smarter devices are constantly being developed to help us manage our everyday lives," said Northwestern's Samuel I. Stupp, who led the experimental studies. "The next frontier is in the development of new science that will bring inert materials to life for our benefit—by designing them to acquire capabilities of living creatures."

The research will be published on June 22 in the journal Nature Materials.

Stupp is the Board of Trustees Professor of Materials Science and Engineering, Chemistry, Medicine and Biomedical Engineering at Northwestern and director of the Simpson Querrey Institute He has appointments in the McCormick School of Engineering, Weinberg College of Arts and Sciences and Feinberg School of Medicine. George Schatz, the Charles E. and Emma H. Morrison Professor of Chemistry in Weinberg, led computer simulations of the materials' lifelike behaviors. Postdoctoral fellow Chuang Li and graduate student Aysenur Iscen, from the Stupp and Schatz laboratories, respectively, are co-first authors of the paper.

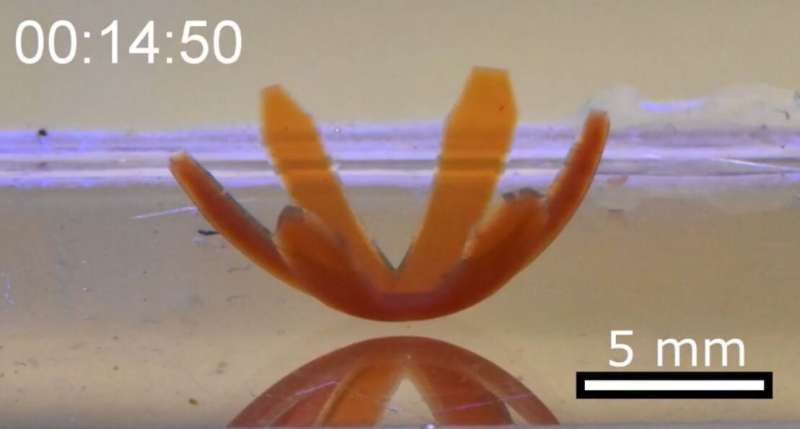

'Hybrid bonding polymer' object crawls on a surface driven by alternating periods of light exposure and darkness. Credit: Northwestern University

Although the moving material seems miraculous, sophisticated science is at play. Its structure comprises nanoscale peptide assemblies that drain water molecules out of the material. An expert in materials chemistry, Stupp linked the peptide arrays to polymer networks designed to be chemically responsive to blue light.

When light hits the material, the network chemically shifts from hydrophilic (attracts water) to hydrophobic (resists water). As the material expels the water through its peptide "pipes," it contracts—and comes to life. When the light is turned off, water re-enters the material, which expands as it reverts to a hydrophilic structure.

This is reminiscent of the reversible contraction of muscles, which inspired Stupp and his team to design the new materials.

"From biological systems, we learned that the magic of muscles is based on the connection between assemblies of small proteins and giant protein polymers that expand and contract," Stupp said. "Muscles do this using a chemical fuel rather than light to generate mechanical energy."

Macroscopic 'hybrid bonding polymer' object bends when irradiated with blue light from the top. Credit: Northwestern University

For Northwestern's bio-inspired material, localized light can trigger directional motion. In other words, bending can occur in different directions, depending on where the light is located. And changing the direction of the light also can force the object to turn as it crawls on a surface.

Stupp and his team believe there are endless possible applications for this new family of materials. With the ability to be designed in different shapes, the materials could play a role in a variety of tasks, ranging from environmental clean-up to brain surgery.

"These materials could augment the function of soft robots needed to pick up fragile objects and then release them in a precise location," he said. "In medicine, for example, soft materials with 'living' characteristics could bend or change shape to retrieve blood clots in the brain after a stroke. They also could swim to clean water supplies and sea water or even undertake healing tasks to repair defects in batteries, membranes and chemical reactors."

More information: Supramolecular–covalent hybrid polymers for light-activated mechanical actuation, Nature Materials (2020). DOI: 10.1038/s41563-020-0707-7 , www.nature.com/articles/s41563-020-0707-7

Journal information: Nature Materials

Provided by Northwestern University