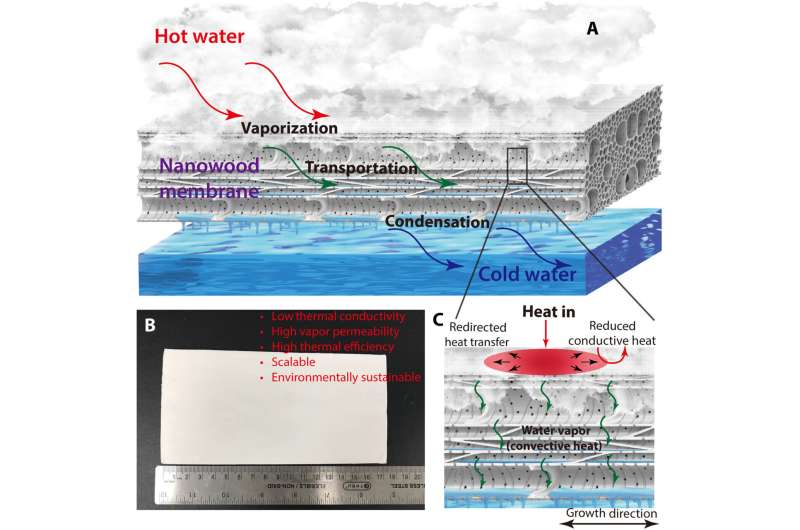

The process schematic of nanowood membranes for membrane distillation (MD). (A) Schematic of MD using the wood membrane. (B) Digital photograph of the nanowood and the corresponding beneficial properties for MD applications. (C) Schematic of the water (vapor) and heat transfer in the wood membrane during MD. Photo credit: T. Li, University of Maryland. Credit: Science Advances, doi: 10.1126/sciadv.aaw3203

During water desalination, membrane distillation (MD) is challenged by the inefficiency of water thermal separation from dissolved solutes, due to its dependence on membrane porosity and thermal conductivity. For instance, existing petroleum-derived membranes have faced major development barriers. In a new report now on Science Advances, Dianxun Hou and colleagues at the interdisciplinary departments of civil, environmental, architectural engineering, materials science and mechanical engineering in the U.S., Norway and China fabricated a robust MD membrane directly from sustainable wood material for the first time.

They used a hydrophobic nanowood membrane with high porosity and hierarchical pore structure with a wide pore size distribution of crystalline cellulose nanofibrils, xylem vessels and lumina to facilitate water vapor transportation. Thermal conductivity was extremely low in the transverse direction of the construct to reduce conductive heat loss, although high thermal conductivity along the fiber allowed efficient thermal dissipation along the axial direction. The membrane demonstrated excellent intrinsic vapor permeability and thermal efficiency. The combined properties of thermal efficiency, water flux, scalability and sustainability made nanowood highly desirable for MD (membrane distillation) applications.

Water scarcity is a global challenge and the United Nations (UN) report that presently nearly half the global population live in potentially water-scarce regions for at least 1 month per year. The problem is exacerbated by climate change and rapid urbanization, evidenced with extensive periods of drought and frequent wildfires in the State of California in the U.S. Desalination can help alleviate water stress by extracting fresh water from a range of saline or contaminated sources including sea-water, brackish ground water or wastewater. Scientists have boosted desalination using nanotechnology and advanced manufacture.

Structural characterization of the nanowood membrane. (A) Photo of the hydrophobic nanowood membrane. (B) Photo that shows hydrophobicity after silane treatment. (C) Water contact angle of the nanowood membrane. (D) SEM images of the nanowood surface that exhibit aligned texture, xylem vessels, and lumina (channels). (E) SEM images that exhibit mesopores [(G) cross section and (H) pits] growing on the walls of the xylem vessels and lumina. (F) SEM images that exhibit microsized pores amid the cellulose fibers. (I) PSD of the hydrophobic natural wood and nanowood membranes. Photo credit: D. Hou, University of Colorado. Credit: Science Advances, doi: 10.1126/sciadv.aaw3203.

Existing water desalination techniques such as reverse osmosis are however energy intensive and at their energy efficiency limit (~50 percent). Researchers are therefore keen to use low-cost and renewable energy sources as an alternative cost-effective strategy to mitigate challenges in energy storage. Membrane distillation (MD) is an emerging, thermally driven separation process based on temperature and vapor pressure using solar, thermal or other renewable sources. In its mechanism of action, water evaporates at the hot feed side of MD cells to diffuse through a porous hydrophobic membrane to condense at the cold permeate side.

During MD, the transport of water vapor can lead to convective heat transfer to reduce the gradient and lower the driving force for mass transfer across the membrane. Scientists envision an ideal MD membrane will combine a large pore size, low pore tortuosity, low thermal conductivity, high porosity, optimal thickness, good mechanical strength, cost-effectiveness and low environmental impact. However, the existing MD membranes made of synthetic polymers do not meet optimal standards due to several shortcomings.

In the present work, therefore, Hou et al. developed the first robust MD membrane directly from sustainable wood as a nature-based solution for water purification. The earth-abundant nanocellulose material is generally used in products with minimal environmental or health impacts to construct scaffoldings, biofuels or water-filters. The materials scientists developed the current version of nanowood by directly removing lignin and hemicellulose with chemical treatment and freeze-drying to preserve the anisotropic nanostructure and the hierarchical alignment of wood fibers.

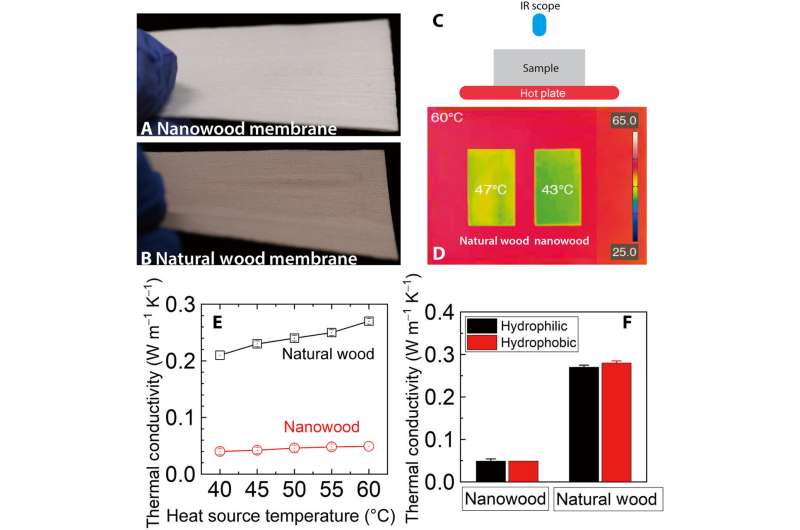

Thermal conductivity characterization of the wood membranes. (A) Photo of the hydrophobic nanowood membrane. (B) Photo of the hydrophobic natural wood membrane. (C) Schematic representation of contact heat source measurement. IR thermographs of (D) the wood membranes. (E) Measured thermal conductivity of the wood membranes from 40° to 60°C. (F) Comparison of the thermal conductivity of the woods at 60°C before and after hydrophobic silane treatment. Error bars represent the SDs based on three independent experiments. Photo credit: D. Hou, University of Colorado. Credit: Science Advances, doi: 10.1126/sciadv.aaw3203

The scientists prepared the wood into an anisotropic and thermally insulating bulk material with high porosity, low thermal conductivity and good mechanical strength as an ideal substrate for the new MD membrane. The research team used nanostructured wood from natural American basswood followed by silane coating to form a hydrophobic surface membrane with high porosity and low thermal conductivity. They then compared the hydrophobic wood membranes with commercial membranes relative to structure and performance during water purification.

The new membranes presented a unique pore structure with naturally formed xylem vessels and lumina in parallel to the membrane surface compared to synthetic commercial membranes with vertical pores. The research team directly observed the natural alignment of cellulose nanofibrils using scanning electron microscopy (SEM). They noted the resulting structure with aligned crystalline nanofibrils held together with intermolecular hydrogen bonds and van de Waal forces. By removing the intermixed lignin and hemicellulose components, the scientists contributed to approximately 70 percent mass loss and improved porosity of the hydrophobic nanowood membrane. Hou et al. used the pores located between the nanofibrils or on the channel walls for water vapor transportation.

Due to the large porosity of the engineered material, the theoretical thermal conductivity of the hydrophobic nanowood membrane decreased from 0.210 to 0.04 W m−1 K−1 at 25°C, to contribute to conductive heat loss reduction, while increasing convective heat transfer. The scientists treated the wood with fluoroalkylsilane (FAS) to induce hydrophobicity, which they verified using water contact angle measurements to obtain contact angles greater than 140 degrees. The values were greater than those observed with commercial membranes such as polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF). The morphology and pore structure remained intact before and after surface treatment. The scientists compared the hydrophobic wood membranes with commercial membranes relative to membrane structures, including pore size dimension (PSD), thermal conductivity and performance.

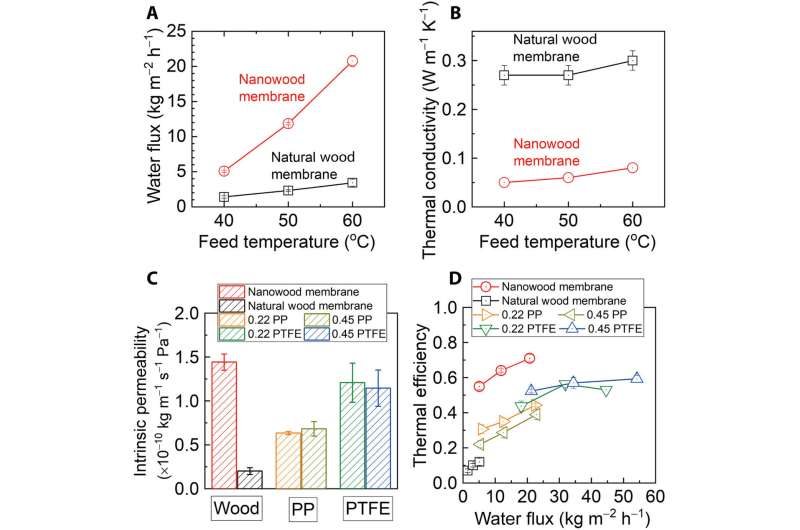

MD performance of the wood and commercial membranes. (A) Water flux and (B) experimental thermal conductivities for the hydrophobic wood membranes with feed temperature continuously varying between 40° and 60°C and distillate temperature of 20°C. (C) Intrinsic permeability of the membranes. (D) Thermal efficiency versus water flux of the wood membranes and commercial membranes. Error bars represent the SDs based on three independent experiments. Credit: Science Advances, doi: 10.1126/sciadv.aaw3203.

To demonstrate the capabilities of thermal insulation for the fabricated hydrophobic nanowood membrane, the researchers tested the specimen under a conductive heat source and stimulated direct contact membrane distillation (DCMD). During the experiments they applied five different temperatures and measured them using an infrared (IR) camera. In the results, the hydrophobic nanomembrane showed low thermal conductivity and anisotropic property when temperatures escalated from 400C—600C. According to the results, the removal of intermixed lignin and hemicellulose during nanowood preparation contributed to significant changes in thermal conductivity of the wood.

Hou et al. then tested the thermally efficient desalination of the nanowood membrane by observing water (vapor) flux through the membranes. Due to increased porosity and pore size, the hydrophobic nanowood membrane demonstrated higher water flux with substantially reduced vapor transfer resistance. They compared the performance of nanowood MD with commercial MDs and proposed the use of thinner wood membranes to fabricate better flux in future studies. The hydrophobic membranes showed good thermal efficiency (71 ± 2% at 60°C) to represent the highest values achieved in MD thus far. In total, the results suggested the larger pore size and wider PSD (pore size dimension) of the nanowood membrane to offset disadvantages from lower porosity.

The newly developed hydrophobic nanowood membrane showed superior properties and MD potential for water desalination. The membrane showed good water influx (water vapor transportation) and excellent thermal efficiency due to high intrinsic permeability and super low thermal conductivity (0.040 W m−1 K−1) to promote convective and conductive heat transfer. In this way, Dianxun Hou and colleagues fabricated a nanowood membrane using a scalable, top-down approach with simple chemical treatments. The newly developed, scalable nanowood membrane is a thermally efficient membrane with great potential to use low-grade heat from diverse sources during membrane distillation (MD) for water desalination.

The scientists can improve the pore size and thickness by selecting other wood species for the process in the future. They also propose the use of electrospinning to engineer nanocellulose fibers. Due to the hydrophilic nature of nanocellulose materials, Hou et al. aim to further improve the efficiency of hydrophobic treatment for membrane durability under high temperature and chemical conditions. The research team intends to further optimize the methods of fabrication to engineer thinner and larger membrane materials for future applications in water desalination

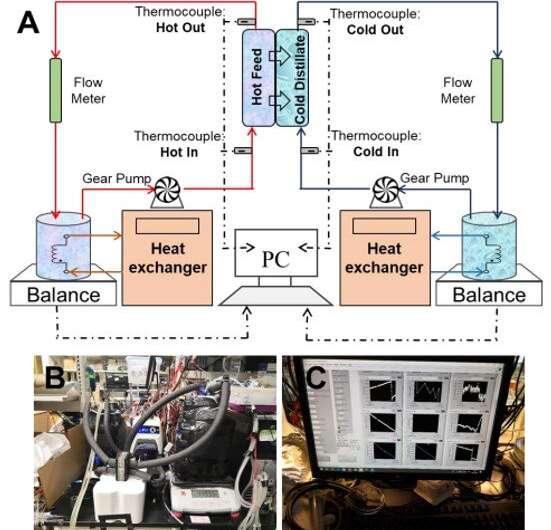

Schematics, images, and control interface of the apparatus for direct contact membrane distillation (DCMD). (A) Schematics of the apparatus for direct contact membrane distillation (DCMD). Visual images of (B) the DCMD reactor and (C) LabVIEW control syst

More information: Dianxun Hou et al. Hydrophobic nanostructured wood membrane for thermally efficient distillation, Science Advances (2019). DOI: 10.1126/sciadv.aaw3203

W. Neil Adger et al. Cultural dimensions of climate change impacts and adaptation, Nature Climate Change (2012). DOI: 10.1038/nclimate1666

Mark A. Shannon et al. Science and technology for water purification in the coming decades, Nature (2008). DOI: 10.1038/nature06599

Anthony P. Straub et al. Harvesting low-grade heat energy using thermo-osmotic vapour transport through nanoporous membranes, Nature Energy (2016). DOI: 10.1038/nenergy.2016.90

Journal information: Science Advances , Nature , Nature Climate Change , Nature Energy

© 2019 Science X Network

![Structural characterization of the nanowood membrane. (A) Photo of the hydrophobic nanowood membrane. (B) Photo that shows hydrophobicity after silane treatment. (C) Water contact angle of the nanowood membrane. (D) SEM images of the nanowood surface that exhibit aligned texture, xylem vessels, and lumina (channels). (E) SEM images that exhibit mesopores [(G) cross section and (H) pits] growing on the walls of the xylem vessels and lumina. (F) SEM images that exhibit microsized pores amid the cellulose fibers. (I) PSD of the hydrophobic natural wood and nanowood membranes. Photo credit: D. Hou, University of Colorado. Credit: Science Advances, doi: 10.1126/sciadv.aaw3203. Hydrophobic nanostructured wood membrane for thermally efficient distillation](https://scx1.b-cdn.net/csz/news/800a/2019/1-hydrophobicn.jpg)