Credit: CC0 Public Domain

An acid used for medicine and to flavor some drinks soon may help make electronic components and certain adhesives more durable and better for the environment.

Purdue University researchers have discovered a method for using tannic acid to help create improved adhesives, coatings and manufacturing composites. The Purdue team is using its discovery for epoxy-based polymers—which are considered among the most versatile and useful adhesive agents because of their excellent mechanical strength and strong sticking power.

"There are few high-temperature hardeners that are sustainable," said Jeffrey Youngblood, a professor of materials engineering in Purdue's College of Engineering. "Our technology is designed to improve sustainability without sacrificing performance."

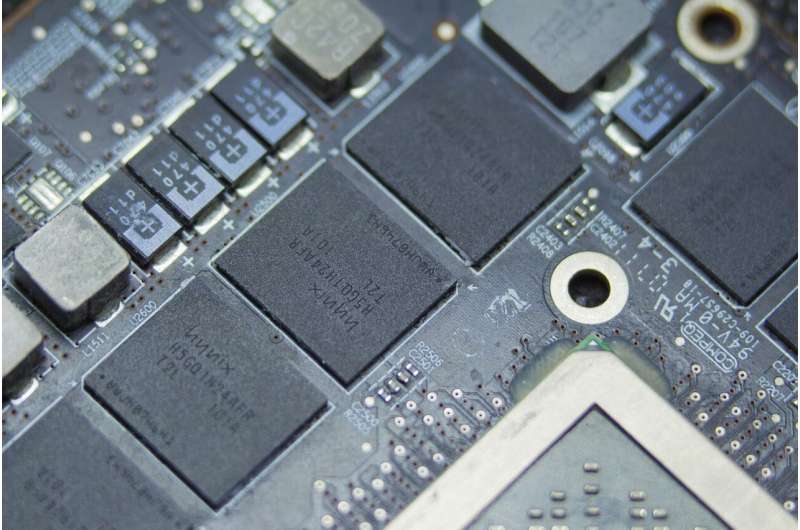

Epoxy polymers are used in a wide range of applications including coatings, adhesives, structural composites, insulating materials and components of electronics. A hardening agent is added to the polymer to ensure stability and stiffness in high-temperature environments.

"We are using tannic acid as the hardener," Youngblood said. "It is more sustainable than other options, has less environmental impact and is relatively inexpensive."

Tannic acid is a well-known, naturally occurring polyphenolic compound used in antioxidants. Youngblood said the team's tannic acid solution also has shown in testing to be stable and maintain needed stiffness when exposed to high temperatures. The other members of the research team include John Howarter, an associate professor of engineering, and Matthew Korey, a National Science Foundation graduate research fellow.

"My research group is heavily involved in developing sustainable materials," he said. "Sustainable materials typically have lower performance, which compromises the public perception and penetration into the market. Here, such a trade-off is not necessary."

Youngblood previously worked on technology involving tannic acid to help make materials flame-retardant. He said this new discovery opens opportunities to continue that research into using tannic acid for fire retardancy.

Provided by Purdue University