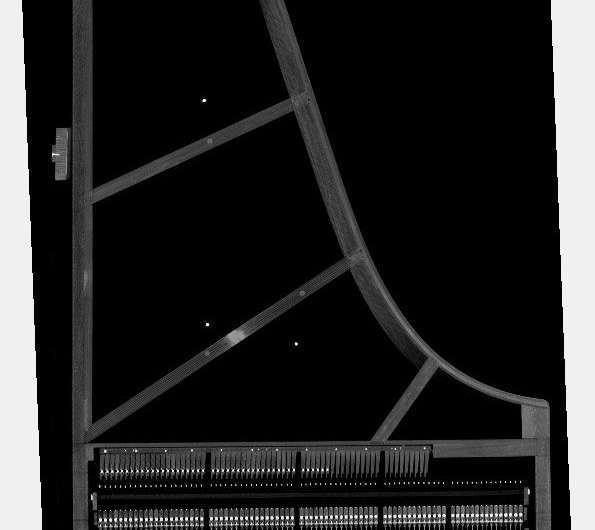

CT scan of a box-valve trumpet, viewed from the exterior. Credit: Fraunhofer EZRT

The internal structure of old musical instruments is of great interest to musicians, restorers, and instrument makers. As part of the MUSICES project, Fraunhofer researchers are using 3-D computed tomography methods to examine historical musical instruments belonging to the collection held by the Germanisches Nationalmuseum (GNM). Based on this experience, they are drawing up guidelines for obtaining the best possible images and measurement results. Until now, there has been no standard for such measurements. The results of the project will be published online.

There is hardly any object that the researchers at the Fraunhofer Development Center for X-ray Technology EZRT, a department of the Fraunhofer Institute for Integrated Circuits IIS, have not investigated using their CT (computed tomography) scanners yet. So far, the facilities have been used to analyze lightweight cast parts, rotor blades, entire cars, and landing flaps made of carbon fiber reinforced polymers, for the purposes of industrial quality control and as a non-destructive method of detecting potential defects such as hairline fissures. In the MUSICES project (see "The MUSICES project at a glance"), the researchers in Fürth joined forces with specialists from the Germanisches Nationalmuseum (GNM) in Nürnberg and the Chair of X-ray Microscopy LRM at the University of Würzburg to take a look inside historical musical instruments, some of which are unique. Being able to examine instruments such as a violin, pianoforte, basset horn and countless others from the inside using 3-D X-rays is an excellent way of evaluating their condition and determining whether, despite their age and possible deterioration due to storage conditions, they are still playable. By analyzing the images, it is possible to see how the instrument was built, including its resonant parts and the materials employed. The images also reveal invisible repairs, signs of damage such as cracks, delamination and woodworm attack, and structural details including the grain and density of the wood. The revelation of these until-now hidden areas is of tremendous value to restorers, conservators, musicians, museum educators and instrument crafters.

But we still lack standards to define the best way of using 3-D CT scanning to study the condition of old musical instruments. The partners in this project are therefore developing guidelines that will enable museums throughout the world to digitalize different types of instruments and obtain images of comparable quality. It's not a trivial matter because it involves defining a large number of innumerable parameters including radiation dose, exposure time, measuring interval and duration, the configuration of the CT scanner, and the algorithms used to reconstruct the volumes and consecutively to mine information from the 3-D datasets.

Credit: Fraunhofer EZRT

Virtual online museum

This is a worthwhile effort because, as Dr. Theobald Fuchs, chief scientist at Fraunhofer EZRT and MUSICES project leader explains: "A large part of the collections of musical instruments held by museums is kept in underground storage facilities. In case of the GNM there simply is not enough exhibition space to showcase all 3500 of them at the same time. The CT digitalization project will enable us to create a virtual museum in which digital facsimiles of these instruments are available to anyone with internet access."

The team has already digitalized more than a hundred instruments dating back over several centuries – from the baroque trumpet and the mouth harmonica to the square piano. Different types of CT systems are needed to scan different-sized instruments. The square piano, for example, is X-rayed utilizing a linear accelerator, which is the source of radiation in Europe's largest CT machine. The XXL X-ray environment consists of two eight-meter-tall steel scaffolding towers and a turntable with a diameter of three meters, housed in a hall covering a surface area of 400 square meters and rising to a height of 14 meters. Smaller string and wind instruments are X-rayed using conventional apparatus. For each test, the object is placed on a turntable between the X-ray source and typically a flat-panel detector, which produces images of very high spatial resolution. A specially designed holder keeps the instrument firmly in place while the X-ray beam penetrates the rotating object. The required dose of radiation varies according to the thickness and density of the material. Depending on the structure and condition of the instrument, the scanning process can take several hours, during which the CT system records several thousand images which are then stitched together to produce a three-dimensional view.

X-ray image of the outer body of a pianoforte. Credit: Fraunhofer EZRT

The researchers aim to publish their results online by January 2018 at the latest. These will not only include the collected CT data but also detailed and comprehensible documentation of all steps in the measurement process. The examination standard defines the CT scanning parameters, and the accompanying set of guidelines provides advice on its application for different instruments.

Openly accessible metadata

Moreover, at the end of the project, all the technical parameters and metadata will be published in a database developed at the GNM. "Ideally, we would like to be able to digitalize the museum's entire collection of historical musical instruments and place the 3-D images online. Our examination standard defines the best way to go about this task," says Fuchs. "One of the many factors that we are now able to quantify is the time needed to digitalize different instruments. For example, a complete X-ray scan of a violin at a resolution of less than 50 microns takes up to 20 hours. This figure can be extrapolated to determine the time needed to scan an amount of x instruments. This produces a specific quantity of voluminous datasets, requiring corresponding amounts of hard disk and network capacity and special software. We have compiled a list of all these requirements." Another advantage of the standard is that it enables the knowledge and experience gained from scanning musical instruments to be applied to other museum collections such as telescopes and other scientific instruments or old weapons.

X-ray view of the internal structure and components of a pianoforte. Credit: Fraunhofer EZRT

Provided by Fraunhofer-Gesellschaft