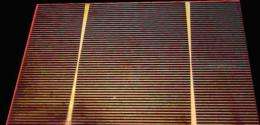

IMEC's i-PERC cell with shallow emitter and Cu metallization.

At the European Photovoltaic Solar Energy Conference (Hamburg, Germany), IMEC presents a large-area solar with a conversion efficiency of 18.4%.

Compared to the standard i-PERC cell process, IMEC's solar cell features a shallow emitter and advanced front metallization using copper plating. The results were obtained on large-area cells (125cm2), proving the industrial viability of the process.

The shallow emitter results in an enhanced blue response, and thus in a higher conversion efficiency than with a standard emitter. For the front contacts, a novel metallization stack is added which is applied to local openings in the antireflective coating. Dr. Joachim John, team manager at IMEC: “Using copper instead of silver adds to the sustainability of solar cell production. IMEC was able to do this because it has extensive experience with copper plating on silicon”. A similar efficiency result was obtained with screen printed contacts, but the long-term sustainability and low-cost potential of Cu-based contacting solutions and the fact that this was a first result obtained without dedicated fine-tuning makes this result particularly encouraging. ”

Dr. Jef Poortmans, IMEC’s Photovoltaics Program Director, states “These cells and the new metallization stack involved are a further successful step in IMEC’s target to develop ever more cost-effective, efficient crystalline Si solar cells - eventually targeting cells that are only 40µm thick with efficiencies above 20%.

Source: IMEC