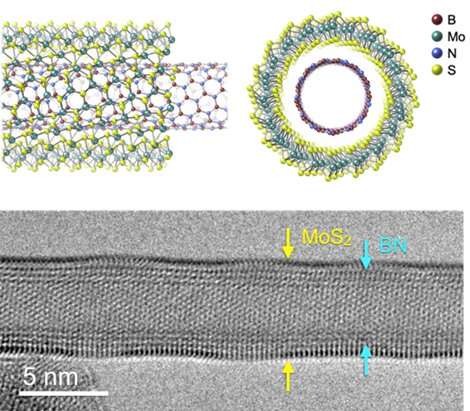

Chemical vapor deposition of molybdenum disulfide on a well-isolated boron nitride nanotube creates a coaxial nanotube structure. Credit: Tokyo Metropolitan University

Researchers from Tokyo Metropolitan University have used a surfactant to disperse insulating boron nitride nanotubes and coat them onto surfaces without bundling. The team demonstrated that heat treatment could remove the surfactant to reveal clean nanoscale templates; chemical vapor deposition could then form coaxial nanotubes on the template using a range of materials. The ability to coat nanotubes onto "inert" insulating structures gives scientists unprecedented access to the properties of new nanotube materials.

Breakthroughs in nanotechnology have made nanotubes and nanosheets easier to come by for materials scientists. But studying them in isolation is far from easy. Because they often come bundled or aggregated, it's tricky to target the exotic optical and electronic properties that come from their reduced dimensionality.

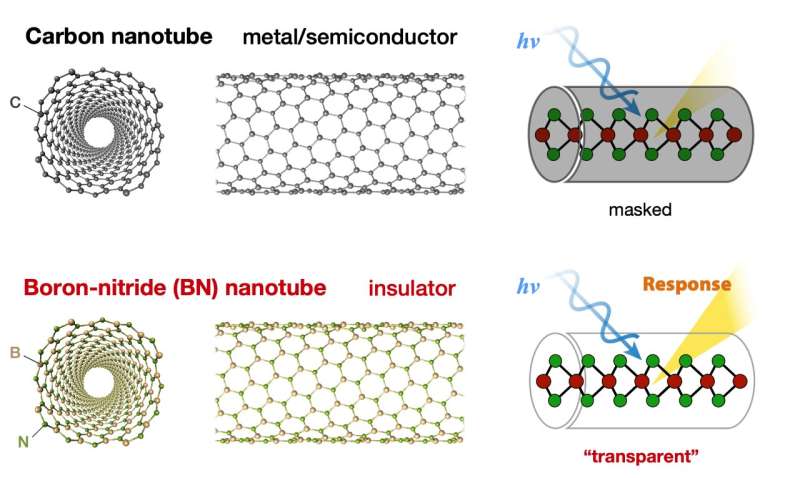

Recent work showed that nanotube materials could be grown on the surface of a carbon nanotube, providing well-separated structures that could potentially be characterized. But carbon nanotubes have conducting properties and strongly absorb light, making it difficult to tell apart the electrical and optical properties of the coated material from those of the original nanotube.

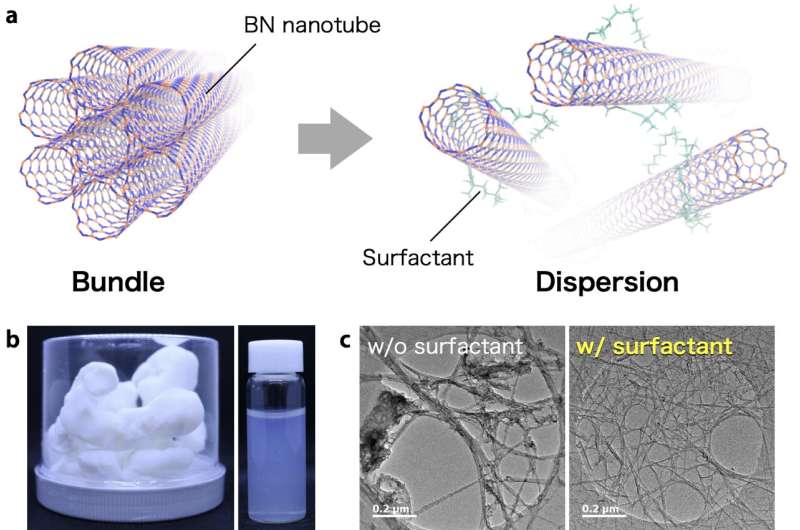

Now, a team led by Assistant Professor Yusuke Nakanishi, Assistant Professor Yohei Yomogida, and Associate Professor Yasumitsu Miyata from Tokyo Metropolitan University has used insulating boron nitride (BN) nanotubes instead as templates for growing nanotubes. This is no mean task: boron nitride nanotubes are notoriously sticky. Though they can be dispersed with a surfactant which helps keeps the tubes apart, it was not clear whether the surfactant could be removed to reveal a clean template. Now, the team has successfully found a surfactant that does not stick to the tubes; they also honed a heat treatment under vacuum which leaves clean, well-isolated insulating nanotube templates.

-

(a) Boron nitride nanotubes tend to come in bundles, but they can be dispersed using a surfactant. (b) Solid (left) and dispersed (right) boron nitride nanotubes. (c) Different network structures formed by boron nitride nanotubes by themselves (left) and with a surfactant (right). Credit: Tokyo Metropolitan University

-

Carbon nanotubes have metallic or semiconducting properties, and strongly block light used to probe the properties of materials. On the other hand, boron nitride nanotubes are insulating and transparent, letting light signals get through. Credit: Tokyo Metropolitan University

Using chemical vapor deposition, a range of materials could be coated onto the templates. The new tube wraps around the original BN tubes, forming something that looks like a nanoscale coaxial cable. Importantly, since BN is an insulating material, the electrical properties of any materials coated can be studied in unprecedented depth. This includes a property known as chirality, the "handedness" in the structure of the atoms in the nanotube which gives rise to a whole range of exotic electronic properties.

In principle, the team believes that their "nano-test-tubes" can be used to template the growth of a whole range of different materials. They've already succeeded with molybdenum disulfide and carbon, with scope for many more. Add to this the optical and electrical inertness of their BN template, and their new platform promises not only material discovery, but also unfettered access to their exotic physicochemical properties. Their research is published in ACS Nano.

More information: Shinpei Furusawa et al, Surfactant-Assisted Isolation of Small-Diameter Boron-Nitride Nanotubes for Molding One-Dimensional van der Waals Heterostructures, ACS Nano (2022). DOI: 10.1021/acsnano.2c06067

Journal information: ACS Nano

Provided by Tokyo Metropolitan University