The deformation mechanism of alginate hydrogel. Credit: LICP

Stimuli-responsive hydrogels not only express excellent biocompatibility, but also can respond when exposed to external stimulation, enabling a wider range of applications in biomedicine. However, at present, stimuli-responsive hydrogel shows poor mechanical properties and limited response to a single stimulus. There is a great need for stimuli-responsive hydrogels with excellent mechanical properties and capability to respond to multiple stimuli.

A team led by Wang Qihua and Wang Tingmei from the Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences recently has issued a report on four dimensional (4D) printing of dual-stimuli response alginate hydrogel.

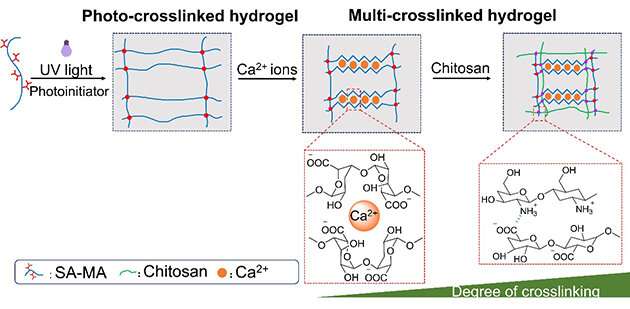

According to the researchers, these hydrogel structures were directly printed with high structural accuracy, following which the hydrogels were immersed in Ca2+ solution and chitosan solution respectively. The 4D printed hydrogels were able to perform step-wise volume contraction.

The soaking strategy adopted was able to not only achieve step-wise volume contraction of the sodium alginate structure, but also continuous enhancement of the mechanical properties of alginate hydrogel with continuous immersion in two solutions.

The printed structures were able to be used for loading-unloading experiments five times and support an object which weighs 361 times its own weight.

This research was published in ACS Applied Polymer Materials and was supported by the National Natural Science Foundation of China, the Chinese Academy of Sciences and Qingdao University.

More information: Pengrui Cao et al, 4D Printing of a Sodium Alginate Hydrogel with Step-Wise Shape Deformation Based on Variation of Crosslinking Density, ACS Applied Polymer Materials (2021). DOI: 10.1021/acsapm.1c01034

Journal information: Applied Polymer Materials

Provided by Chinese Academy of Sciences