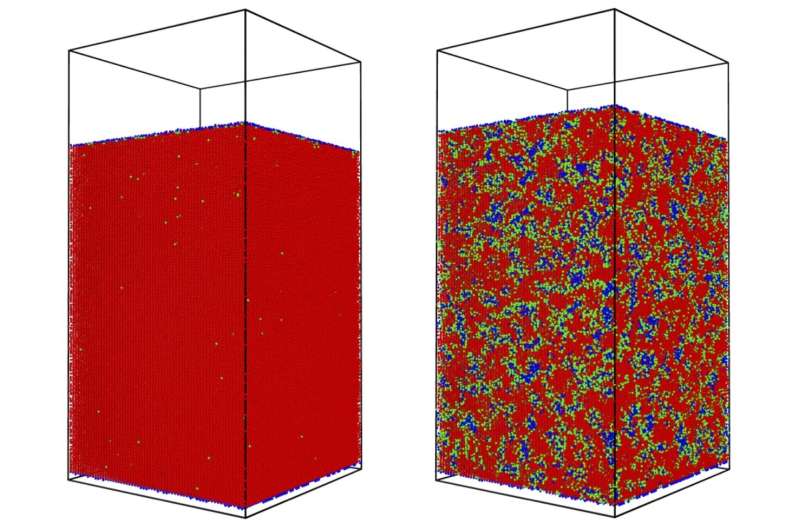

Computer simulations of the structural changes in tungsten metal five trillionths of a second after rapid heating with a laser pulse. Each dot represents an atom in the material. Colors indicate whether the atom is part of an ordered, solid state (red); a disordered, liquefied state (blue); or a state in between (green). While pristine tungsten (left) remains a solid, radiation damage causes the metal to melt at the same temperature. Credit: SLAC National Accelerator Laboratory

Radiation damage lowers the melting point of the metal tungsten, an effect that could contribute to material failure in nuclear fusion reactors and other applications where materials are exposed to particle radiation from extremely hot fusion plasma. That's the result of a study, published today in Science Advances, that was led by researchers at the Department of Energy's SLAC National Accelerator Laboratory.

To mimic the damage materials can sustain under the harsh conditions of a fusion experiment, the team bombarded tungsten samples with energetic ions. Then, they heated the samples with a high-power laser and "filmed" how the samples' atoms responded with SLAC's ultrafast "electron camera," an instrument for ultrafast electron diffraction (MeV-UED). They found that damaged tungsten liquefied at a lower temperature than pristine tungsten. Combining their experimental data with advanced simulations allowed the researchers to quantify, for the first time, how the ultrafast melting process is affected by radiation damage.

The results could aid the design of fusion reactor materials, for instance by providing ideas for dealing with damage sites, the scientists said. They also underline the importance of high-energy upgrades to SLAC's Linac Coherent Light Source (LCLS) X-ray laser and of power enhancements to its laser facility, which would pave the way for even more detailed studies of materials under extreme conditions.

Laser-induced melting of radiation-damaged tungsten captured with SLAC's instrument for ultrafast electron diffraction (MeV-UED). The instrument’s beam of highly energetic electrons passes through the tungsten sample and produces a characteristic scattering pattern on a detector (rings), from which researchers can determine the atomic structure of the sample. The pattern’s changes over time reveal the atomic details of the rapid melting process. Credit: SLAC National Accelerator Laboratory

Computer simulation of the rapid melting process in radiation-damaged tungsten following heating with a high-power laser pulse. Each dot represents an atom in the material. Colors indicate whether the atom is part of an ordered, solid state (red); a disordered, liquefied state (blue); or a state in between (green). The movie shows how the material quickly transitions from a solid to a liquid state. Credit: SLAC National Accelerator Laboratory

More information: Mianzhen Mo et al. Visualization of ultrafast melting initiated from radiation-driven defects in solids, Science Advances (2019). DOI: 10.1126/sciadv.aaw0392

Journal information: Science Advances

Provided by SLAC National Accelerator Laboratory