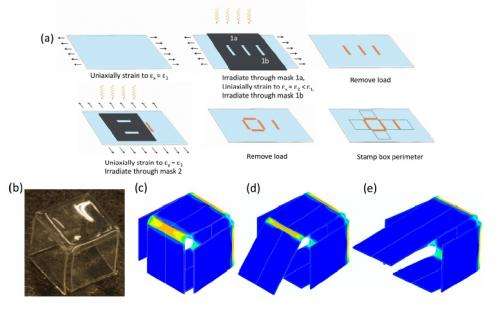

A six-sided box fabricated by photo-origami is constructed by straining and irradiation to form hinges. (a) The photo-origami protocol; (b) a fabricated closed box; and (c), (d), and (e) a simulated box with closed, partially open, and open tops. Image caption: Ryu, et al. © 2012 American Institute of Physics

(Phys.org) -- Replacing the need for nimble fingers, researchers have demonstrated how to make origami using light of a specific wavelength. They call the new folding technique photo-origami, and it could potentially be used as a way to manufacture 3D structures.

The team of mechanical engineers led by Professor Martin Dunn of the University of Colorado at Boulder has published a paper on their simulations and experiments of photo-origami in a recent issue of Applied Physics Letters.

“[We have developed] a non-contact method to bend and fold polymer films in precise, 3D programmable ways, guided by computational simulations,” Dunn told Phys.org.

As the researchers explain in their study, there are several different methods for creating materials that can fold by themselves in a programmable manner. Most of these methods involve attaching an actuator onto the material and applying an external actuation force. Finding a way to make the material fold by itself without using these “parasitic elements” could greatly simplify the process, which could enable more diverse applications.

Because photo-origami only uses light and a mechanical straining force to fold materials, it could potentially serve as a simple, automated sequential folding process. In their study, the researchers experimentally demonstrate how photo-origami works using a flat, two-dimensional polymer that contains photoinitiators. First, the polymer is stretched to create a mechanical strain. Then light is applied to a specific area of the polymer, such as along a line to be folded, which causes the photoinitiators to disassociate into free radicals. The highly reactive radicals then fragment and reform polymer chains, resulting in stress relaxation in the chosen area. This redistribution of stress through the material causes a change of shape as the material strives to achieve mechanical equilibrium, folding along the chosen line.

That process results in a single fold. For each additional fold, the irradiation, and potentially straining, steps are repeated. When the steps are performed in a specific sequence, the technique can produce complex shapes. To demonstrate, the researchers fabricated a heart and a six-sided closed box.

“In principle, this could make many complex structures consisting of bends and folds in arbitrary directions and sequences,” Dunn said. “The computational simulations can be used to design myriad structures, many that we could not conceive without simulations.”

As a form of technical origami, photo-origami could enable applications far beyond origami's original purpose as a creative art. Technical origami can be used in situations in which an object must be stored and transported and later deployed for use. This need arises, for example, for space-based solar arrays, automobile airbags, tissue engineering, shopping cartons, and photovoltaic cells that optimally capture sunlight throughout the day. Origami could also be used to fold molecules into specific shapes for the purpose of tailoring their molecular properties.

Although this demonstration involved macroscopic-scale folding, the approach could also be used at the micro and nano scales. In the future, the researchers plan to further investigate how photo-origami can be extended to manufacturing processes.

“We plan to create smaller, more precise mass-fabricated structures and endow them with multiple physical functionalities,” Dunn said.

More information: Jennie Ryu, et al. “Photo-origami – Bending and folding polymers with light.” Applied Physics Letters 100, 161908 (2012). DOI: 10.1063/1.3700719

Journal information: Applied Physics Letters

Copyright 2012 Phys.Org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.