A. Bonito-Oliva, F4E Project Manager for Magnets, R. Harrison, F4E Technical Officer for Magnets, standing next to Europe’s first Toroidal Field coil winding pack. ASG Facilities, February 2016. Credit: F4E

Powerful superconducting magnets will confine ITER's plasma which is expected to reach 150 million ˚C. Basically, an impressive magnetic shield will entrap the hot gas and keep it away from the walls of the vessel of the world's biggest fusion machine. Discover the manufacturing progress of ITER's first Toroidal Field coil. It is 14 m high, 9 m wide and 1 m thick. Its weight is approximately 110 tonnes which compares to that of a Boeing 747!

One of the biggest and most complex magnets in history is being manufactured at the ASG facilities, Italy. This gigantic "D" shaped coil will be form part of the system that will confine ITER's super-hot plasma which is expected to reach 150 million ˚C. Basically, an impressive magnetic shield will entrap the hot gas and keep it away from the walls of the vessel of the world's biggest fusion machine.

F4E is responsible for the supply of 10 out of the 18 TF coils that ITER will need to operate. Witnessing the first TF coil taking shape is a turning point for the project and the 600 people having contributed to this milestone from at least 26 companies. This is the result of various contracts starting in 2008 when F4E started its collaboration with several suppliers for the production of Europe's TF conductor, which reached a length of 20 km.

Iberdrola, ASG and Elytt Energy, have used parts of this conductor to manufacture Europe's first TF coil. Winding, sandblasting and heat treatment have been some of the main steps taken in order to fit the conductor into stainless steel plates, known as radial plates, manufactured by CNIM and SIMIC. Piece by piece the conductor had to be lifted, wrapped, insulated and placed back in the grooves of the plates before it got covered. Then, the structure containing the conductor has been laser welded and wrapped with insulating material, before going through impregnation.

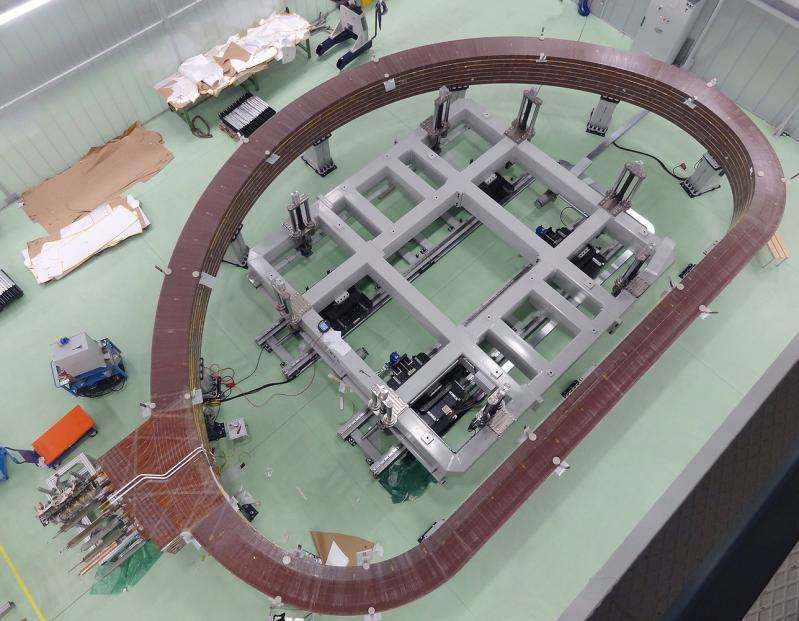

iew of Europe’s first winding pack, the inner-core of a Toroidal Field coil, which will magnetically confine ITER’s plasma. ASG Facilities, February 2016. Credit: F4E

To create the inner-core of the TF coil, a pack of seven of these structures had to be stacked, electrically jointed, wrapped, insulated and impregnated. Pipes through which cold liquid helium will circulate inside the magnet to help it reach a superconducting state and instruments to measure its performance have also been added. Each of these packs, known as a winding pack in the ITER jargon, is 14 m high, 9 m wide and 1 m thick. Its weight is approximately 110 tonnes which compares to that of a Boeing 747!

For Alessandro Bonito-Oliva, F4E's Manager for Magnets, and his team, this has been an accomplishment of significant importance. "Thanks to our determination to meet the tight planning for magnets and the excellent collaboration between F4E and its suppliers we are heading towards Europe's first TF coil, which also happens to be a first for ITER. Seeing a magnet of such complexity taking shape suggests that we can deliver some of the most technically challenging systems of ITER. Sharing expertise and good communication between F4E, ITER International Organization and Japan's Domestic Agency for ITER have been fundamentally important for the achievement of this milestone and will continue to be as production is still ongoing.

So what are the next stages for the inner-core of the first TF coil? The stacking of the first pack has been completed and the electrical insulation material is being applied. When its vacuum-pressure insulation is concluded it will be transferred to SIMIC to conduct a series of tests. Then, it will be inserted in the massive case of the coil and in the end the final casting process will be performed, during which additional epoxy resin will be injected to fill in any remaining gaps.

And what about the progress of the other TF components? In March the production of radial plates for which F4E is responsible has accelerated reaching 45 out of a total of 70. Meanwhile, the manufacturing of the components of the second TF coil have been completed paving the way for its assembly.

Provided by Fusion for Energy