Pressure helps to make better Li-ion batteries

Lithium titanium oxide (Li4Ti5O12, LTO), a "zero-strain" anode material for Li-ion batteries (LIBs), exhibits excellent cycling performance. However, it shows poor conductivity, which is the major drawback and limits its applications. In a recent paper published in National Science Review, it is reported that static compression can highly improve the conductivity of LTO by pressure-induced amorphization and promoting ion migration defects for Li+. The results suggest amorphous LTO is a better anode material for LIBs.

Rechargeable Li-ion batteries are crucial parts for home electronics and portable devices such as cell phones and laptops. One can imagine how the life we have today would be like without cell phones and internet. Li-ion batteries (LIBs) are also growing in popularity for electric vehicle which can help to highly reduce the emission of CO2 and diminish the serious greenhouse effect on the earth. All these demands call for superior Li-ion battery materials with better performance such as higher capacity, longer life time, lower cost, etc.

Lithium titanium oxide (Li4Ti5O12, LTO) spinel experiences negligible volume change during lithium insertion and extraction and is regarded as a "zero-strain" anode material for LIBs. Due to its great structural stability, LTO exhibits excellent cycling performance, making it a promising anode for LIBs in electrical vehicle and large-scale energy storage areas. However, LTO shows poor electronic and ionic conductivities, limiting its applications. Therefore, improving its conductivity becomes crucial.

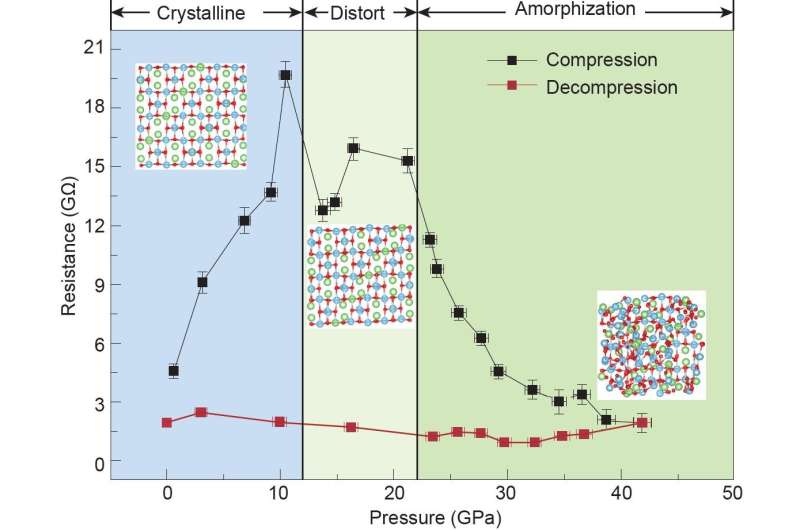

In a recent research article published in the Beijing-based National Science Review, scientists at the Center for High Pressure Science and Technology Advanced Research, Institute of Geochemistry, and Institute of Physics of Chinese Academy of Sciences, and George Mason University, Carnegie Institution of Washington, and Argonne National Laboratory of USA present their results on the studies of phase stability and conductivity of LTO under high pressure. It was found that the LTO spinel structure starts to distort due to the significant difference in compressibility of the building blocks, LiO6 and TiO6 octahedra in LTO at low pressures. The strong highly distorted structure transforms into amorphous eventually as pressure over around 270 thousands times normal atmospheric pressure. Remarkably, the amorphous LTO can be decompressed down to ambient pressure and displays much better conductivity than crystalline LTO. "These findings may offer a new strategy for improving the conductivity of LTO anode in Li-ion batteries using a high-pressure technique." said Dr. Lin Wang, the corresponding author of the article.

To understand the significant enhancement of conductivity in the amorphous phase, the ionic transport properties of crystalline and amorphous LTO were investigated by first-principles molecular dynamics simulations. Theoretical calculations revealed that the amorphous phase induced by high pressure can highly promote Li+ diffusion and increase its ionic conductivity by providing ion migration defects. "All of these findings increase the understanding of the relationship between structure and conducting properties of LTO" Dr. Wang added.

More information: Yanwei Huang et al, Li-ion battery material under high pressure: amorphization and enhanced conductivity of Li4Ti5O12, National Science Review (2018). DOI: 10.1093/nsr/nwy122

Provided by Science China Press