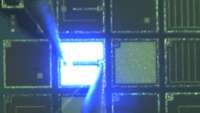

All set and ready to glow

A new technique that paves the way for manufacturing affordable LED light bulbs is to be exploited in the UK, in a deal that researchers say could have a dramatic impact on carbon emissions.

The process, developed at the University of Cambridge, will be utilised by Plessey, a semiconductor manufacturer based in Plymouth. It involves growing gallium nitride crystals on silicon and could drastically reduce the cost of making LEDs for lighting in offices and homes.

Light-emitting diodes, or LEDs, are the small, coloured lights currently used in electronic equipment, bicycle lights and roadside signs. Many scientists see them as the ideal replacement for old-fashioned tungsten filament light bulbs, which are being phased out by the EU because of the amount of electricity they waste and the consequent impact on carbon emissions.

Researchers estimate that a worldwide switch to LEDs, which are far more energy-efficient, would enable the closure of 560 power plants and result in annual CO2 savings equivalent to the output of all the cars on the planet.

LEDs are also being designed to give off a more natural quality of light, which will be better for people’s health. They could potentially be used as “smart lighting” that can switch itself on or off when a person enters or leaves a room, or adjust its brightness according to the amount of daylight.

Until now, however, they have been very expensive to produce, mainly because, historically, the gallium nitride crystals used in LEDs could only be grown on sapphire. Researchers around the world have been racing to find an effective technique for growing on silicon instead, which would drive down production costs and make LEDs more affordable for light bulb companies.

Now a team led by Professor Sir Colin Humphreys at the Department of Materials Science and Metallurgy, University of Cambridge, has developed an effective method. This will be commercialised by a new arm of Plessey, called Plessey Lighting, which will initially make LEDs on silicon for external manufacturers, but in time hopes to develop its own light bulbs in-house.

“We’ve got higher efficiency for growing gallium nitride on silicon than anyone else we know,” Humphreys said. “Potentially this is a deal that puts Britain right at the forefront of LED research.”

“LED light bulbs currently cost as much as £40, but we expect to be able to reduce that cost by a factor of five by growing on silicon. Mass manufacturing may reduce the cost further. Eventually I think that we will see LED lighting being fitted throughout the world.”

The potential return on value for money is high. LEDs last for 100,000 hours at a time, compared with the 1,000 hour lifetimes offered by tungsten filament light bulbs and the 10,000 hours claimed for fluorescent lighting. The average light bulb in Britain is on for four hours every day. So, on average, LED light bulbs would only have to be changed once in every person’s lifetime.

More significant, however, are the likely benefits for the planet. Because tungsten filament light bulbs lose much of their energy as heat, just 5% of the energy they consume is used as light. Fluorescent tubes range from 20% to 25% efficiency. LEDs, however, are currently about 30% efficient and Humphreys hopes to raise that figure to 60% in time.

This means that they require far less energy than conventional bulbs. In the UK alone, the researchers estimate that the nationwide use of LEDs would save 15% of the electricity generated by power stations, resulting in a similar reduction in CO2 emissions. There are also potential cost savings: a recent (2010) US Department of Energy report estimates that savings of $20 billion per year would result if LED light bulbs became widespread in the US.

With over 10 years of funding -including a grant of more than £6 million awarded in December 2010- the Engineering and Physical Sciences Research Council (EPSRC) has funded from it's inception the research which has led to this innovative breakthrough.

Professor David Delpy, EPSRC CEO said: "By bringing new ideas about materials and devices together we can produce LEDs that are highly efficient and thus beneficial to our environment, cheap to buy and, unlike compact fluorescent lamps, produce an attractive colour of light to make homes and offices pleasant and healthy places to be. In the end, we hope the products of this research really will be lighting the future."

The technique developed by Humphreys resolves several problems with trying to grown gallium nitride on silicon. In particular, it addresses difficulties to do with thermal expansion under the growth temperature of 1,000 degrees. Gallium Nitride expands at a very different rate to silicon and when the two substances cool down, the material tends to crack.

Humphreys’ team have been able to introduce layers to the process that put the gallium nitride in a state of compression before it heats up. “This compression balances the tension when it cools down, which allows the material to relax,” he said. “As a result, we can grow LED structures which are totally crack-free.”

The new process will grow LEDs on 6-inch silicon wafers. Each costs about £20; cheaper than the 2-inch sapphire wafers used in the past, and ten times more LEDs can be grown on a 6-inch wafer than on a 2-inch. Plessey was chosen because it already has the equipment to manufacture silicon wafers of this size. In addition, its broader work in electronics means that, in time, the company may be able to develop “smart lighting” from LED light bulbs as well.

“It’s very important to us that this research will be exploited here in the UK,” Humphreys added. “If we had stopped at the research stage, our work would probably have been picked up and commercialised overseas. This way, we can create more jobs in a low-employment part of the country and potentially turn Britain into a major centre for better, greener lighting.”