WUSTL engineers provide free code to help build better batteries

(Phys.org) —Lithium-ion batteries, such as those used in electric vehicles, are in high demand, with a global market value expected to reach $33.1 billion in 2019. But their high price and short life need to be addressed before they can be used in more consumer, energy and medical products.

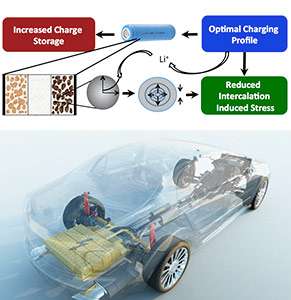

Venkat Subramanian, PhD, associate professor of energy, environmental & chemical engineering at Washington University in St. Louis, and his team have developed a way for lithium-ion battery developers to determine in early stages whether a new material for the batteries will work. The team developed a freely available code that battery developers can use as a model to determine the optimal profile needed to charge a lithium-ion battery as well as any stresses that might be put on the materials used.

"This is a back of the envelope calculation," says Subramanian, an expert in lithium-ion batteries. "Before you invest millions of dollars to go into manufacturing full-time, you can develop models and codes similar to this and look at this initial data to extrapolate and predict how it will work."

The research was recently published in Physical Chemistry Chemical Physics.

In a lithium-ion battery, lithium is stored in metallic form inside particles, Subramanian says. The metal goes in and out of the particles, creating stress, cracking and potential failure.

"With this model and algorithm, we can use materials that are newly developed and those currently thought of as bad materials because of significant stress generation," Subramanian says. "Combining stress effects with optimization algorithms can help derive smart charging profiles that take advantage of stress dynamics in such a way that it ensures faster charging of a battery."

The code, designed for a Windows platform, is available for free download at www.maple.eece.wustl.edu/Contr … ressinmaterials.html.

Subramanian says software development such as this code is an important part of developing new lithium-ion batteries.

"When newer materials and systems are being developed for batteries, for solar and for storage, simultaneous development of software, algorithms and hardware are going to be important," Subramanian says. "We're not going to wait 10 years and find the best material and the best battery, and then start developing the software. You want to be able to start the software development as we develop the new model and algorithms and then adapt it to newer things as they come along."

More information: Suthar B, Ramadesigan V, De S, Braatz R, Subramanian V. "Optimal charging profiles for mechanically constrained lithium-ion batteries." Physical Chemistry Chemical Physics, 2014, 16, 277-287.

Journal information: Physical Chemistry Chemical Physics

Provided by Washington University in St. Louis