Waste that is brimming with energy

Together with the Italian GARBO corporation, the University of Greenwich, United Kingdom, and the University of Padua, Italy, as well as the midsized company EAAT from Chemnitz, Germany, the HZDR researchers are working on a technological solution for waste treatment.

Silicon is the material of choice on the fast growing solar market because it converts solar energy into electric power in a relatively efficient manner. When producing silicon wafers, though, the photovoltaic industry loses about 50 percent of the valuable original material. The objective of the EU project SIKELOR, which is coordinated by the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), is to process silicon waste in an industrially viable and a resource-friendly manner.

The semiconductor material silicon is used as very thin wafers in standard solar modules. But a substantial portion of the silicon, which was won at the expense of high energy input, is lost during production. When cutting the wafers out of large blocks, fine silicon powder is produced as a by-product; and this waste amounts to nearly as much as the material which is found in the end-product. This is due to the fact that the saw which is used in this process – for example, a wire made of silicon carbide or of diamond – is about as thick as a single wafer. Together with the Italian GARBO corporation, the University of Greenwich, United Kingdom, and the University of Padua, Italy, as well as the midsized company EAAT from Chemnitz, Germany, the HZDR researchers are working on a technological solution for waste treatment.

"The silicon chippings in the sawdust need to be as free as possible of impurities prior to re-melting. That's why we have to first separate them from the fluid that is used as part of the sawing process. Next, the dust is condensed and molten. However, the resulting dust contains impurities. Since the chippings' surface is large compared to their volume, oxidation takes place such that a lot of silicon dioxide is allowed to build up. In addition, carbon particles end up in the sawdust and, during melting, silicon carbide is produced as an unwanted waste product. Our goal is to come up with an economically feasible process for industrial recycling of silicon waste," notes Dr. Sven Eckert who coordinates the project at the HZDR. Just recently, he met in Brussels with the coordinators of 13 other projects revolving around resource efficiency which had also been selected. The European Union supports these projects with a total of 40 million euros.

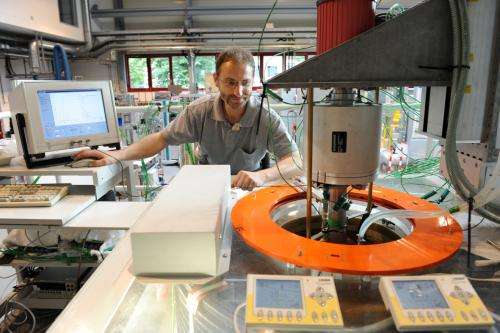

The SIKELOR (Silicon kerf loss recycling) project, which is scheduled to run for three years and is funded with 1.4 million euros, is to lead to an industry-compatible process. Electromagnetic stirring and separating plays a special role in this process. "We're addressing specifically the question of how to configure the magnetic field and the coil so that we can stir the impure mixture as efficiently as possible. Our current focus is on separating the impurities with the help of electromagnetic stirring and having them migrate to the edge where they can be concentrated and removed," explains Dr. Eckert. But the desired result can only be achieved through a tricky combination of the magnetic field parameters. That's why a demonstrator is to be built at the HZDR which will permit the researchers to investigate the individual process steps with the help of a model alloy similar to silicon. The insights thus gained will then be applied in a second demonstrator at the University of Padua. That's where the silicon, which melts at 1,410 degrees Celsius, can be processed. The Chemnitz-based EAAT corporation is designing and will deliver the requisite power supply system capable of operating at different heating stages while at the same time permitting different frequencies to be set for the magnetic fields.

Currently, the photovoltaic modules installed in Germany have a combined output of approximately 32 gigawatts; the branch plans to expand this output to more than 200 gigawatts. Innovative concepts which help improve the degree of efficiency continue to be in great demand. If the SIKELOR project manages to successfully process the raw material which accumulates as dust during wafer production, then the solar industry will be able to reduce its costs. Currently, silicon is traded on the global market for about 18 dollars per kilogram – but experts anticipate a considerable increase over the next few years. The partners of the SIKELOR project anticipate a price of only ten dollars per kilogram of recyclable material for their recycling procedure.

Provided by Helmholtz Association of German Research Centres