February 10, 2011 weblog

New Si based photovoltaic cells may be the light of the future

(PhysOrg.com) -- A team of scientists at the Japan Advanced Institute of Science and Technology, or JAIST for short, led by Tatsuya Shimoda, a professor at the JAIST School of Materials Science, has created an amorphous silicon photovoltaic cell by applying a liquid Si.

This world's first inphotovoltaics has a conversion efficiency of 1.79% which, when applied to a pin-type cell whose i-layer was made with the coating process, according to JAIST researchers.

They also have hopes that when the efficiency of the amorphous silicon photovoltaic cells improves in the future, it may become possible to mass-produce the Si PV cells by using a roll-to-roll method.

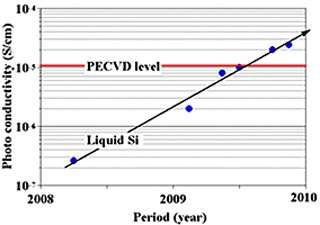

The research group started with cyclopentasilane, a liquid Si, but they did not reveal any further specifics of the liquid Si. We do know that it was developed by emitting ultraviolet rays at CPS in a carbon hydrogen solvent in order to polymerize part of the CPS to make a polysilane. This Liquid Si was developed during the period between 2006 and 2007.

The problem of forming an uniform polysilane film was solved by carefully examining controlled parameters and optimizing the burning conditions of the polysilane film and reduced the density of the unattached hands to 1 x 1016/cm3.

More details of the development process were not made public. The pin-type amorphous Si PV cells were put on the glass substrate by using a new coating process, which allowed the p- and n-layers to be formed by using the chemical vapor deposition method. The conversion efficiency of the cell that has their p-, i- and n-layers formed by using this coating process was 0.51%. This is tempered by the fact that the thickness of the new cell's i-layer is 120nm. This makes them significantly thinner than the amounts found in existing amorphous Si PV cells, which have a thickness of 250nm.

Researchers at JAIST believe that if this thickness is increased the efficiency will improve.

More information: Information in Japanese: translate.google.com/translate … news/2011/02/10/011/

© 2010 PhysOrg.com