Preventing hydropower turbine failure

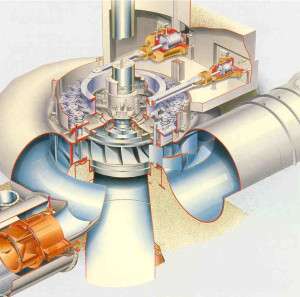

The Francis turbine is the most common type of water turbine used in Norwegian hydropower plants, and has been for many years. About half of the world's Francis turbines are found in Norwegian plants.

But for the past few years, more and more of these turbines have been fracturing. The problem has been particularly pronounced in high-pressure turbines, which run at head heights of 200-300 metres.

"At least five of the main hydropower plants in Norway have had turbine problems in the past few years, among them Svartisen," says Professor Ole Gunnar Dahlhaug of the Department of Energy and Process Engineering at the Norwegian University of Science and Technology. "Svartisen had to stop production for six months, and the power company lost huge amounts of money."

"We think we know what's causing the problem, but we aren't able to make the calculations that would enable us to better understand it" says Dahlhaug. "It has to do with resonance, and an interaction between pressure from the water and the steel in the turbine blades."

Explained simply: a changing water current, such as one caused when production starts and stops a lot, will result in an oscillating pressure on the steel turbine blades. If the frequency of this oscillation approaches the fundamental frequency of the material, it causes a resonance that can weaken the steel. It's essentially the same as the apocryphyl crystal glass breaking when an opera singer hits the right note.

Dahlhaug was previously head of the Norwegian Hydropower Centre (NKVS), which is a collaboration between several universities, research institutions, the hydropower industry and the Norwegian government.

New power regime

Hydropower production can be turned on and off on short notice, and can therefore be adjusted to changes in market prices and power needs. This flexibility means that it is a good option in combination with newer sustainable energy sources, such as wind and solar energy. Norwegian hydropower plants can work as a sort of green battery to deliver sufficient power on cloudy or still days.

But it turns out that the Francis turbines aren't able to handle this flexible running schedule.

The problem seems to have started as a result of the new power production regime implemented in the 1990s. Power production was no longer controlled by grid system operation, but rather by the power market. Individual power companies could choose when they ran their turbines, mostly decided by changing prices and demand in the power market.

"The turbines installed in the 1960s and 1970s were designed to run more or less all the time, with a constant amount of pressure. Now they can be started and stopped as many as ten times a day. The turbines can't handle it. In some cases, the actual steel in the blades has cracked," Dahlhaug says.

Newer turbines have also had problems—a turbine in Driva failed after only ten days. A new turbine also failed at the Svartisen power plant.

Industry collaboration

To solve this problem, researchers, power companies and turbine manufacturers have all come together to collaborate. Competing businesses are sharing and comparing data in several different research projects, all working towards the same goal.

"This is the first time that I know of the whole industry coming together as such a team on something that really is basic research," Dahlhaug says. "But it is a technical problem that everyone has in common. The knowledge isn't something that we want to compete about— it's not something that anyone wants to miss out on."

The most important job is to make a simulation tool to see what happens inside a turbine under different conditions. Or to simply find a method to calculate what the turbines can handle under different amounts of strain.

Like a crystal glass breaking

"We think we know the cause of the problems, but we aren't able to calculate it," says Dahlhaug.

It has to do with resonance, and the interaction between the pressure of the running water and the steel in the turbine blades. Explained simply: a changing water current, such as one caused when production starts and stops a lot, will apply an oscillating pressure to the steel turbine blades. If the frequency of this oscillation approaches the fundamental frequency of the material, it causes a resonance that can weaken the steel. It's essentially the same as a crystal glass breaking when an opera singer hits the right note.

Unfortunately, finding the fundamental frequency of the steel isn't as simple as you'd think. Factors such as submersion in water and rotation can cause it to change.

"There are a lot of variables that we can't control here, and that we aren't able to calculate yet. Running simulations of conditions that change so much requires immense amounts of computing power," Dahlhaug explains.

Difficult to calculate

Statkraft has many high-pressure Francis turbines. The first incidence of major damage to turbines was in Leirdøla kraftverk in 1978, says Kjell-Tore Fjærvold, Section Manager of Mechanical Technology at Statkraft.

"Since then, there have been a number of similar incidents at Statkraft as well as other power companies in Norway and in Europe, with similar turbines. We've also had problems with several of the high-pressure Francis turbines more recently. The challenge is that providers aren't able to calculate the appropriate amounts of strain and stress due to varying water currents during construction of the turbines. This means that we as customers can't be sure if the parts we buy will have problems when we use them," Fjærvold explains.

Need for basic research

Project Francis 99 started last year. Different groups are all comparing calculation methods and data based on a common reference model. The first project summit was held last year, with representatives from 16 universities, as well as from all of the main turbine providers in the sector.

This project will soon be followed by High Head Francis, a new four-year research project. It is being initiated by Statkraft through NVKS, but will be run by NTNU. This is also a collaboration with power companies and turbine providers, Dahlhaug explains.

"Usually, businesses are interested in more practical research. But in this case, the industry is taking part in basic research. Statkraft has a representative working 200-300 hours a year, and other businesses are contributing with technology researchers," he says.

The third step is an EU project that will be started next year, assuming that it is funded.

"Hydropower plays a key role in providing energy, along with other sustainable energy sources. But first, we need to understand what is happening, and be able to calculate the requirements for safe, resilient turbines," Dahlhaug concludes.

Provided by Norwegian University of Science and Technology