Microbes strip power from poo

EPSRC-funded scientists have developed a process using microbes which removes the need to use electricity to process sewage at treatment plants. The microbes can also be used to produce large quantities of valuable hydrogen gas, a source of clean energy.

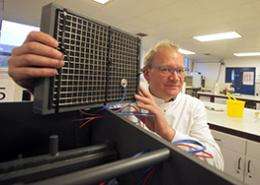

The team at Newcastle University and Northumbrian Water Ltd unveiled their research ("Fuelling the future") at the British Science Festival. They trialled out a hydrogen Microbial Electrolysis Cell (MEC) on sewage at a waste water treatment works on Tyneside.

As the raw sewage is pumped through the Microbial Fuel Cell, microbes growing on the carbon felting strip the electrons off the 'food' or sewage and transfer these to the anode, producing electricity. Meanwhile the hydrogen ions that are left migrate to the cathode where they are reunited with the electrons which have been topped up with just enough energy to allow them to turn the hydrogen ions into hydrogen gas. The energy required to "top up" the electrons is less than the energy released. So the system is potentially energy positive.

Currently this hydrogen is released, but the team say that the hydrogen could be collected as a clean and valuable fuel or, better still, the electrons and hydrogen could be combined to make higher value organic chemicals.

Currently around two per cent of all electricity used in the UK is used to treat wastewater.

Professor Tom Curtis from Newcastle University says: "We spend a lot of electricity treating sewage and it's totally unnecessary. Waste water contains two to three times more energy than we use to treat it so if we can harness that energy we can not only close the loop on sewage treatment to create a totally self-treating system, we will also have spare energy to use elsewhere.

"What's really clever about this system is that it works on raw sewage at ambient temperature. Most anaerobic digesters require a high-energy, concentrated food source and heat to work properly which means the water has to be removed first and this is an energy-expensive process.

"What we have developed is a system that feeds on the waste as it arrives at the plant – the whole lot goes in and the microbes do all the hard work."