This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Study enhances plasticity of spontaneous coagulation cast oxide ceramic green bodies

Spontaneous coagulation casting (SCC), a new type of colloidal forming process, has garnered significant attention since 2011 due to various advantages of a high bulk density and non-toxicity, as well as the ability to achieve dispersion and coagulation with very low additions (< 1 wt%) of copolymers of isobutylene and maleic anhydride (PIBM).

Further research has revealed that the green bodies formed by this method are brittle, and the smaller the powder particle size used, the more brittle the green bodies are. This paper reports a study on the plasticity enhancement of oxide ceramic green bodies shaped by SCC.

The team published their article in the Journal of Advanced Ceramics on May 21 2024.

"The objective of this study was to employ plasticizers in the PIBM gel system to enhance the plasticity of oxide ceramic green bodies with different particle sizes. The water-soluble plasticizers, glycerol and polyethylene glycol (PEG), were selected for containing polar groups (-OH) and nonpolar sections," said the authors.

The research team quantified the plasticity of the green bodies with different plasticizers and different particle size powders by analyzing the flexural stress-strain curve and impact toughness, as well as carrying out drilling experiments in conjunction with practical processing.

"The particle size of the ceramic powder played a critical role in determining the appropriate selection of plasticizers. For submicron powders, it was found that glycerol with low addition and shorter molecular chains had a more pronounced plasticizing effect. As the particle size decreased, PEG with a longer molecular chain enhanced plasticity.

"An increase in the amount was required for nanoscale powders. The particle sizes of 0.45 μm, 0.18 μm, and 50 nm showed an improvement in plasticity with the addition of 1 wt% glycerol, 1 wt% PEG, and 5 wt% PEG, respectively. The drilling test revealed that there was nearly no cracking around the holes in the green bodies with plasticizers," the authors said.

Additionally, the authors found that "plasticizers had little effect on the sintering characteristics of the green bodies."

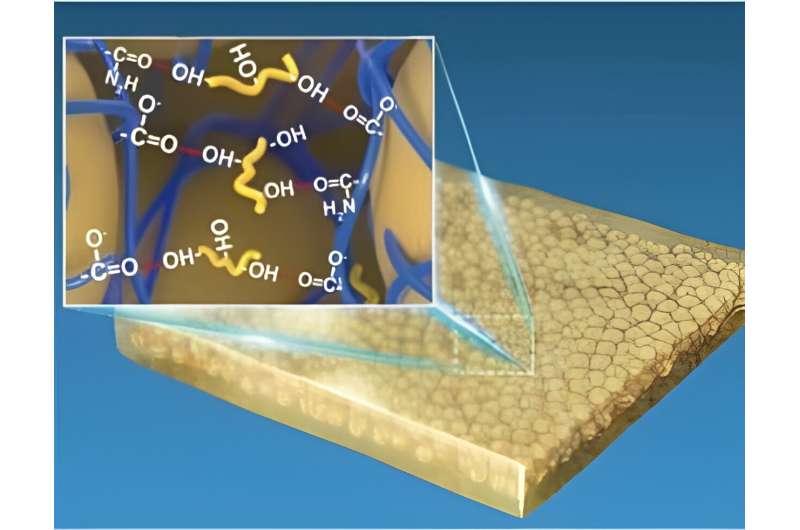

Regarding the plasticity mechanism, the authors explained, "The introduction of glycerol and PEG molecules will interact with the PIBM molecules in ceramic slurries by hydrogen bonding and hydrophobic effect, influencing the interaction between PIBM molecules, thereby modifying the gel network structure. Upon drying, this network encapsulates the surface of ceramic particles to form a cocoon-like structure … to alleviate the hard contact between the particles."

The research team expects to prepare large-sized samples, thus further expanding the industrialized applications of spontaneous coagulation casting.

The contributors include Juanjuan Wang, Jin Zhao, Junyan Mao, Wenlong Liu, Haohao JI, Jian Zhang and Shiwei Wang from the State Key Laboratory of High Performance Ceramics and Superfine Microstructure, Shanghai Institute of Ceramics, Chinese Academy of Sciences.

More information: Juanjuan Wang et al, Enhanced plasticity of spontaneous coagulation cast oxide ceramic green bodies, Journal of Advanced Ceramics (2024). DOI: 10.26599/JAC.2024.9220879

Provided by Tsinghua University Press