This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

B₄C–TiB₂ composite ceramics with adjustable mechanical and electrical properties

In recent years, electro-conductive composite ceramics have gradually become a research hotspot in the functionalization of structural ceramics. However, the improvement of conductivity is generally achieved at the cost of increasing the content of conductive phases or sacrificing the mechanical properties of the composite ceramics.

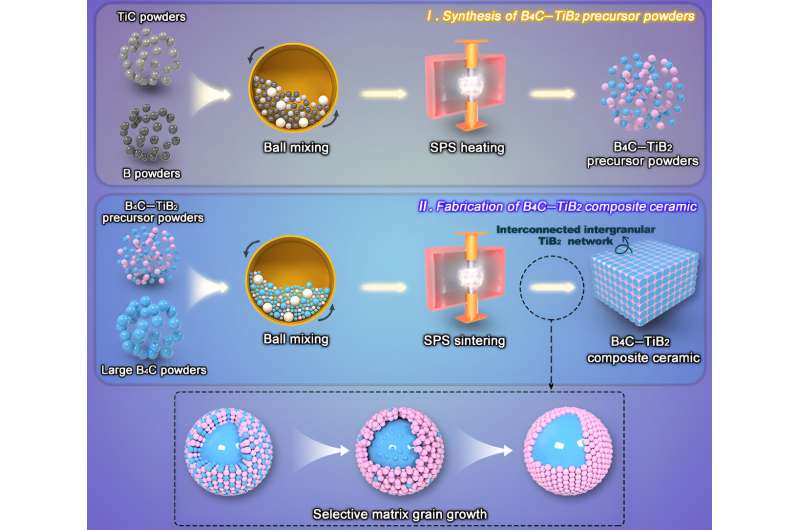

Therefore, achieving high conductivity of composite ceramics at low conductive phase content is of great significance. In a recent study, electrically conductive B4C–TiB2 composite ceramics containing only 15 vol% TiB2 were prepared by a two-step spark plasma sintering process, and their mechanical and electrical performances were adjusted by the optimal particle size coupling of raw material powders.

A team of material scientists led by Songlin Ran from Anhui University of Technology in Maanshan, China recently prepared highly electro-conductive B4C–TiB2 ceramics by a two-step spark plasma sintering method.

The three-dimensional interconnected intergranular TiB2 network consisting of large B4C grains and small TiB2 grains established an excellent conductive path for the passing of electrical current, which was beneficial to the improvement of electrical conductivity. Moreover, they have also achieved controllable adjustment of the mechanical and electrical properties of B4C–TiB2 ceramics by the optimal particle size coupling of raw material powders.

The team published their review in Journal of Advanced Ceramics on April 25, 2024.

"In this work, we prepared highly electro-conductive B4C–TiB2 ceramics via a two-step method based on the novel selective matrix grain growth strategy. During the sintering progress, small B4C grains were completely consumed, leaving small TiB2 grains around B4C grains to form the three-dimensional interconnected intergranular TiB2 network.

"As a result, more conductive channels were formed and thus improving the electrical conductivity of the composites," said Dr. Ran, the corresponding author of the paper, a professor in the School of Materials Science and Engineering at Anhui University of Technology.

B4C–15 vol% TiB2 composite ceramic prepared from 10.29 µm B4C and 0.05 µm TiC powders exhibited a perfect three-dimensional interconnected conductive network with a maximum electrical conductivity of 4.25×104 S/m, together with excellent mechanical properties including flexural strength, Vickers hardness and fracture toughness of 691±58 MPa, 30.30±0.61 GPa and 5.75±0.32 MPa·m1/2, respectively, while the composite obtained from 3.12 µm B4C and 0.8 µm TiC powders had the best mechanical properties including flexural strength, Vickers hardness and fracture toughness of 827±35 MPa, 32.01±0.51 GPa and 6.45±0.22 MPa·m1/2, together with a decent electrical conductivity of 0.65×104 S/m.

"The method proposed in this paper can prepare highly electro-conductive ceramics at low conductive phase content, which greatly reduces the production cost and also provides a new strategy for the regulation of microstructure and properties of composite ceramics," said Dr. Ran.

The next step is to restructure the three-dimensional network and construct a more perfect conductive network by introducing ceramic particles, whiskers, fibers, etc. In addition, the effect of the multiple conductive phases on the microstructure, electrical properties and mechanical properties of the composite ceramics need to be investigated in detail to reveal the conductive mechanism.

Other contributors include Jun Zhao, Xingshuo Zhang, Zongning Ma, Dong Wang and Xing Jin from Anhui University of Technology in Maanshan, China; and Chaohu University in Hefei, China.

More information: Jun Zhao et al, Tuning mechanical and electrical performances of B4C–TiB2 ceramics in a two-step spark plasma sintering process, Journal of Advanced Ceramics (2024). DOI: 10.26599/JAC.2024.9220874

Provided by Tsinghua University Press