This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers improve the plasticity of ceramic materials at room temperature

Researchers in Purdue University's College of Engineering have developed and validated a patent-pending method that could expand the industrial applications of ceramics by making them more plastically deformable at room temperature.

Plasticity or plastic deformability is a material's ability to be deformed by compression, tension or shear into a specific shape or geometry without breaking. Typically, ceramic materials exhibit very limited plastic deformability under room temperature.

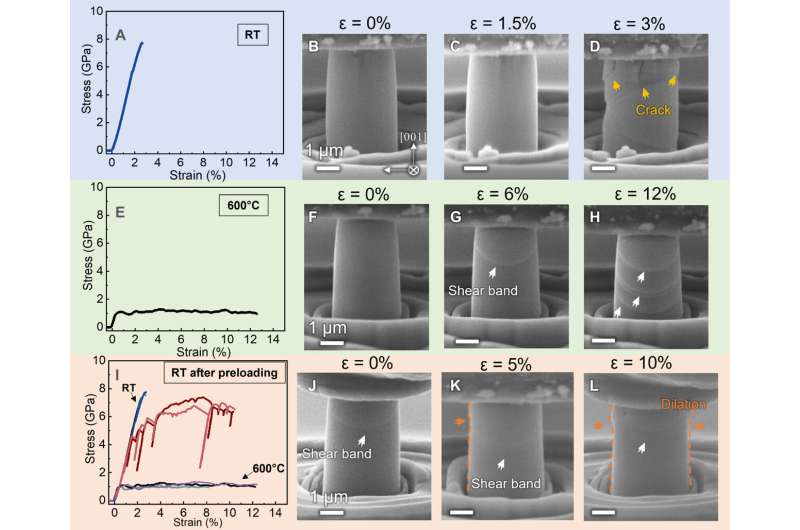

Haiyan Wang and Xinghang Zhang lead a Purdue team whose method improves ceramic room-temperature plastic deformability by first introducing high-density defects in brittle ceramics under high temperatures. Wang is the Basil S. Turner Professor of Engineering and Zhang is a professor of materials engineering in Purdue's School of Materials Engineering.

"Such a strategy can prominently improve the room-temperature plastic deformability of ceramics, and holds the promise to inject ductility, or the ability to be drawn into near net shape, of ceramics in the near future," Zhang said.

The research has been published in Science Advances. This approach complements their previous research about improving ceramic plastic deformability via the method of flash sintering, which was published in a 2018 issue of Nature Communications.

"Not all ceramic materials can be processed by the flash sintering method," Wang said. "This new method can be generalized to nearly all ceramic materials."

Ceramics: Beneficial, yet brittle

Ceramic materials are used as structural materials in industries like aerospace, transportation, power plants and manufacturing; and in applications such as bearings in engines and machines, capacitors, electrical insulating materials, electrodes in batteries and fuel cells, and thermal barrier coatings in high-temperature machines.

They are mechanically strong and chemically inert; resist wear and corrosion; insulate against heat and electricity; and are harder, and have higher melting points, than metals. These attributes mean ceramic materials can be used to cut metals or contain molten metals and sustain high stresses at high temperatures.

Ceramics also are brittle at room temperature; they bend only at high enough temperatures when dislocation activity can be activated. Metals, by contrast, bend without breaking at room temperature.

Wang said ceramics have few dislocations, causing their brittle nature. Dislocations are defects in materials that change the arrangement of atoms in a structure.

"A dislocation can glide within crystals to enable plastic deformability at certain stress levels," Wang said. "However, in ceramic materials, it is difficult to nucleate dislocations at room temperature, as the fracture stress in ceramics is much less than the stress to nucleate dislocations at such temperatures."

Zhang said, "In contrast, metallic materials are ductile because they easily nucleate a very high density of dislocations. And dislocations are mobile in metals at room temperature, significantly improving their ductility. So the way to improve plasticity for ceramics is to nucleate abundant dislocations in ceramics before we start to deform them."

Technique to improve ductility

Wang said extensive efforts have been made to enhance the deformability of ceramics, but with only limited success.

The Purdue team has introduced dislocations into ceramic materials by preloading them during deformation at high temperatures. Chao Shen, a graduate student on the team, said once the ceramic specimens are cooled, the dislocations improve the plasticity of ceramics at room temperature.

"This method is more widely applicable to a broad range of ceramics than the method of flash sintering, since not all ceramic materials can be processed by flash sintering," Wang said. "Preloading dislocations may also be much easier to scale up in practice for large-scale processing and treatment of ceramics than flash sintering."

The technique has been tested and validated in their laboratory on various ceramic systems and ceramic pillars of different dimensions.

"After the preloading treatment, single-crystal titanium dioxide exhibited a substantial increase in deformability, achieving 10% strain at room temperature," Zhang said. "Aluminum oxide also showed plastic deformability, 6% to 7.5% strain, using the preloading technique."

The research team—including Wang, Zhang and R. Edwin Garcia, professor of materials engineering, and their graduate students—will collaborate with industry on large-scale demonstrations of this approach in various ceramics systems.

Wang and Zhang disclosed the innovation to the Purdue Innovates Office of Technology Commercialization, which has applied for a patent from the U.S. Patent and Trademark Office to protect the intellectual property.

More information: Chao Shen et al, Achieving room temperature plasticity in brittle ceramics through elevated temperature preloading, Science Advances (2024). DOI: 10.1126/sciadv.adj4079

Journal information: Nature Communications , Science Advances

Provided by Purdue University