January 5, 2024 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Microtexturing soft materials to remove aqueous microfoulants

The process of crystallization fouling is a phenomenon where scale forms on surfaces. It is widespread in nature and technology and affects the energy and water industries. Despite previous attempts, rationally designed surfaces with intrinsic resistance remain elusive due to a lack of understanding of how microfoulants adhere in dynamic aqueous environments.

In a study now published in Science Advances, Julian Schmid and a team of researchers in surface engineering in Switzerland and the U.S. studied the interfacial dynamics of microfoulants by using a micro-scanning fluid dynamic gauge system to demonstrate a rationally developed coating that removes 98% of deposits under shear flow conditions.

The dynamics of water and energy

Water and energy are interconnected resources, where water is required to produce energy for transport, desalination, and water treatment. The finite nature of these resources and growing global challenges including climate change and population growth, however, place them under increased stress. Passive methods to repel scale formation include surface engineering, interfacial materials, and coatings, which are attractive alternatives for sustainability and are also cost-efficient.

Researchers had also previously focused on developing rigid antifouling surfaces that alter the surface energy of materials to eliminate fouling. Materials scientists have shown a growing interest in the development of interfacial materials and coatings that improve antifouling properties using the material's inherent barriers.

In this new work, Schmid and colleagues developed a new method to study the physics of microfoulant adhesion and created a micro-scanning fluid dynamic gauge. The scientists revealed three underlying mechanisms of microfoulant removal to design a microtextured coating and tested its scalability under laminar and turbulent flow conditions. The outcome can shed light on properties of crystallization and particulate fouling, and lead to the design of interfacial materials as antifouling surfaces to address the challenges of the water–energy nexus.

Bioinspired materials

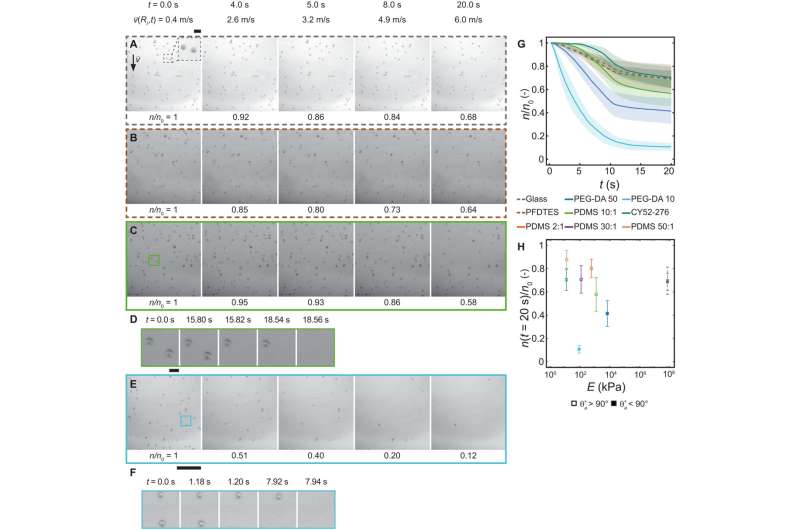

Nature features exceptional examples of super-wettability and transport systems that have contributed to the development of bioinspired repellant substrates for the investigation of the dynamics of crystallite-water interactions. Schmid and colleagues quantified the microfoulant removal from substrates with varying compliance by determining their surface wettability. For instance, to remove calcium carbonate crystallites, the team used a tunable laminar water shear flow and simultaneously visualized the process by pumping water through a glass capillary to generate shear stress.

Schmid and team quantified the passive shear-driven aggregate removal process as well. For instance, when the team applied the method to a rigid glass substrate that had undergone crystallization fouling under shear flow, they observed the changing number of crystallites on the surface relative to the initial value. Such glass surfaces can be made hydrophobic by treatment with fluorosilane and a soft silicone to highlight the intricate nature of substrate-crystallite interactions and demonstrate surface properties with microfoulants.

Model microfoulants

The individual events of crystallite removal were rapid, which has substantial implications for antifouling or scalephobic materials as it allows the removal of crystallites before the build-up of tenacious scale layers. To understand the mechanisms underlying enhanced repellence toward scale-based coating, the materials scientists replaced complex scale crystallites that vary in size with comparably sized spherical polystyrene microparticles to study the effect of water shear, their Young's modulus, wettability and thickness.

Aside from crystallization fouling, Schmid and team used particulate fouling by settling microfoulants on the coating as another subset of the method. Most microfoulants were smaller than the thickness of the coating, although ice and hydrate foulants exceeded this thickness. The scientists performed additional experiments to detect the microfoulant-coating interactions.

Designing and developing a scalephobic coating

Existing research has shown how uniform, non-porous hydrogels with low swelling behavior require a polymer content of at least 40% by weight. To follow a similar fabrication process, Schmid and colleagues opted to increase the polymer content of the coating to 50% by weight, which negatively affected the adhesion and removal properties of the coating.

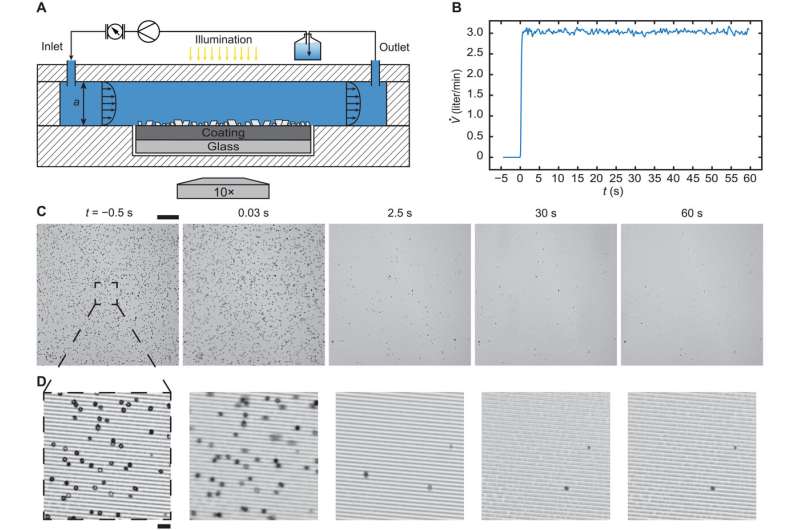

The outcomes highlighted the excellent scale-phobicity of the coating. For instance, the first crystallites were removed from the microtextured polymer almost immediately after initiating flow. From the outset, the team removed a substantial number of crystallites to obtain a near clean surface to highlight the properties of scalephobicity of the designed coating under turbulent flow conditions.

Outlook

In this way, Julian Schmid and team incorporated adhesion and interfacial fluidic theories to develop a method to study the underlying physics of microfoulant adhesion on and removal from engineered materials. They developed this technique based on a previously established method to analyze antifouling materials to improve the approach to study antifouling.

The method provided insights into the dynamics of the full behavior of the coating. The outcomes revealed the interactions between foulants, substrates and water to remove surface adhered crystallites under flow conditions. The team explored the versatility of antifouling materials and how the design strategies varied depending on the dominant fouling mechanism.

For instance, with particulate fouling, rigid coating surfaces performed well, whereas soft coating outperformed with crystallization fouling. Hydrogels on the other hand had a low polymer content and therefore showed excellent removal performance for both microfoulants and crystallites. For nonporous and hydrophilic hydrogels, the polymer content had to be increased, which Schmid and team mitigated by microtexturing the surface.

The materials scientists realized intrinsically scalephobic surfaces and microtextured soft hydrogels to remove predominant regions of crystallites. The outcomes provide significant details for designing antifouling and scalephobic surfaces for adhesion and interfacial transport research under heat transfer and flow conditions.

More information: Julian Schmid et al, Imparting scalephobicity with rational microtexturing of soft materials, Science Advances (2023). DOI: 10.1126/sciadv.adj0324

Journal information: Science Advances

© 2024 Science X Network