This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

A self-wrinkling coating for impact resistance and mechanical enhancement

Polymer coating is widely used as a protective layer in various fields such as surface anti-corrosion, anti-penetration and anti-impact. How to enhance the mechanical properties of coatings such as impact resistance is important but challenging, under the condition of the existing materials systems and processes.

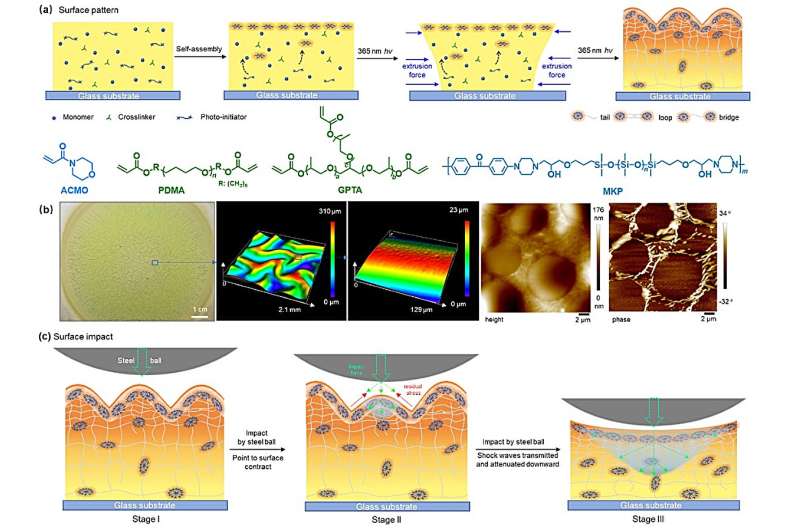

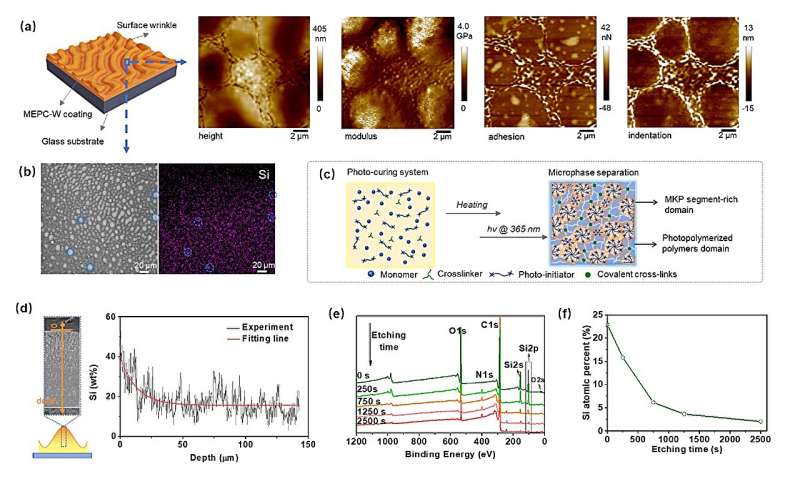

Inspired by natural organisms' bottom-up fabrication and energy dissipation mechanisms, researchers considered four critical factors in material design (chemical composition, nano/microstructure, architecture and manufacturing techniques). They developed a self-wrinkled photo-curing coating, comprising a microphase-separated structure with a gradient cross-linked architecture, as protective materials.

The self-wrinkled surface morphology induced by photo-polymerization and the intrinsic gradient architecture generated by gradient cross-linked polymer networks are critical factors for energy dissipation and impact resistance of the cured coating, providing mechanically enhanced characteristics, which was verified both theoretically and experimentally.

-

(a-b) The schematic surface coating, surface morphology of the self-wrinkling photo-curing coating.(c) The mechanism of surface microphase separation of the coating surface during heating and UV irradiation. (d-f) Verification of the gradient cross-linked structure of the self-wrinkling photo-curing coating. Credit: Science China Press -

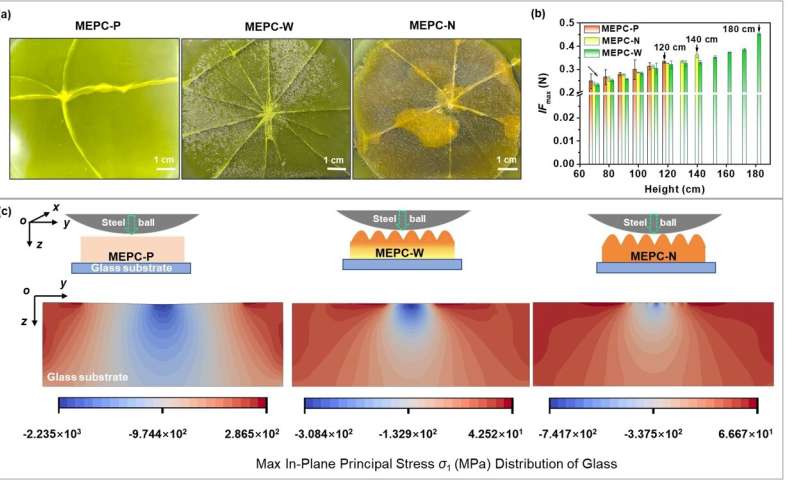

(a) The digital images of the glass substrates coated with different surface coating after crumbling impacted by falling ball. (b) The maximum impact force (IFmax) -height curves of pure glass substrate coated with different surface coating. (c) Simulation of anti-impact properties of different surface coating for glass substrates. Credit: Science China Press

Compared with the highly sophisticated tools (i.e., molding, nano-/micro-imprinting, laser ablation and soft lithography) this self-wrinkled coating was fabricated through the same one-step approach as the conventional photo-curing coating, opening up new possibilities for photo-curing coatings.

The work is published in the journal Science Bulletin.

More information: Jin Li et al, Self-wrinkling coating for impact resistance and mechanical enhancement, Science Bulletin (2023). DOI: 10.1016/j.scib.2023.08.021

Provided by Science China Press