December 27, 2023 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Developing a futuristic elastomer with ultrahigh strain-induced crystallization

Strain-induced crystallization can strengthen, toughen, and facilitate an elastocaloric effect in elastomers. The resulting crystallinity can be induced by mechanical stretching in common elastomers that are typically below 20%, with a stretchability plateau.

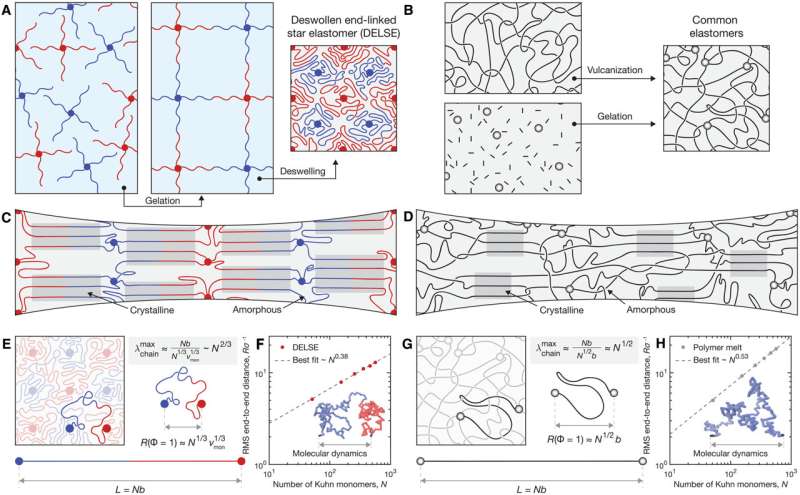

In a new report now published in Science Advances, Chase M. Hartquist and a team of scientists in mechanical engineering and materials sciences at MIT and Duke University in the U.S. used a class of elastomers formed by end-linking to achieve a percentage of strain-induced crystallinity.

The deswollen and end-linked star elastomer abbreviated as DELSE reached an ultrahigh stretchability to scale, beyond the saturated limit of common elastomers, to promote a high elastocaloric effect with an adiabatic temperature change.

Strain-induced crystallization

The process of strain-induced crystallization is common in elastomers and gels where amorphous polymer chains can transform into highly oriented and aligned domains due to an applied mechanical strain. Since the oriented and aligned crystalline domains can resist crack extension and blunting to facilitate crack deflection, the process of strain-induced crystallization preserved the network integrity, while achieving close to 100% recovery in seconds.

The method plays a key role in a variety of applications, including elastocaloric cooling, and strain-based actuation.

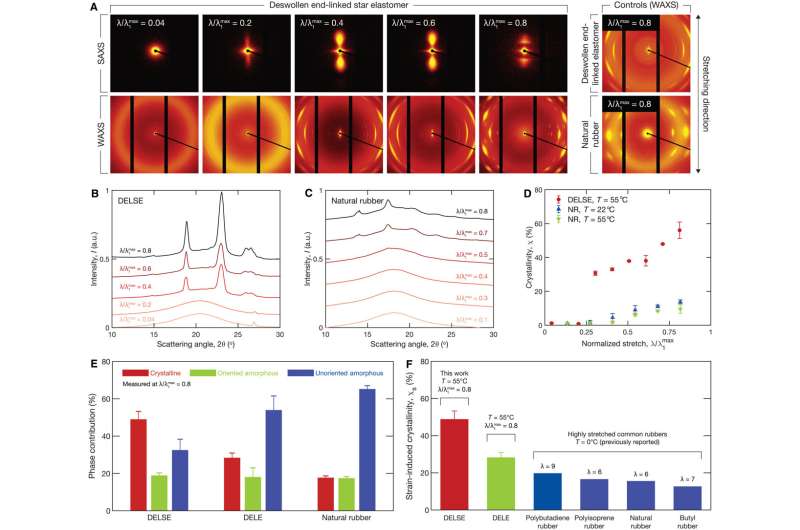

The typical process of strain-induced crystallinity in common elastomers is below 20%, while natural rubber only achieves about 15% crystallinity when stretched to six times its initial length at room temperature. In this new work, Hartquist and a team of researchers described a class of deswollen, end-linked star elastomers to achieve up to 50% strain-induced crystallinity. The scientists credited the ultrahigh strain-induced crystallization to a uniform network structure and a high stretchability to obtain the expected outcomes.

To study the additional features of the elastomer, the team used X-ray analysis to show how the structure and strain-induced deswollen and end-linked star elastomer promoted crystallinity when compared to common elastomers. The research team further analyzed the crystal structure formed using detailed X-ray analysis, where the deswollen and end-linked star elastomers displayed a diffraction spot to mark the formation of poly(ethylene dioxide) crystals in a helical structure. This elastomer promoted higher strain-induced crystallinity, when compared to common elastomers.

Mechanical performance and elastocaloric cooling

The research team conducted mechanical characterization at 60°C to investigate ultrahigh strain-induced crystallization in deswollen end-linked elastomers, which effectively promoted high toughness, with low stress-stretch hysteresis. Hartquist and the team reinforced the softest materials by introducing reversible bonds to induce large stress-stretch hysteresis.

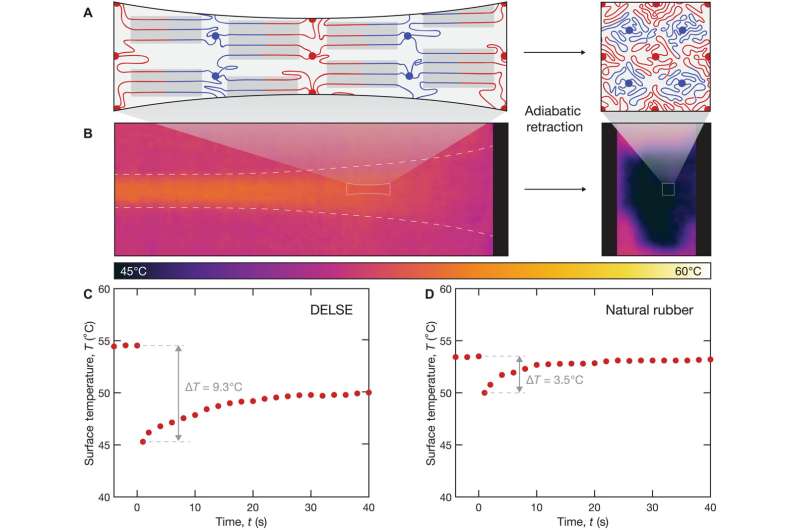

The researchers further studied the stretchability of elastomers to show how the materials stretched beyond the limits of entangled networks for broader applications. They then studied the potential to use a caloric material for solid state cooling applications by investigating the elastocaloric effect in deswollen end-linked star elastomers, and compared the outcomes with conventional elastomers.

The scientists investigated the potential to use a caloric material for solid state cooling applications by studying elastocaloric effects in deswollen end-linked star elastomers when compared with natural rubber. An ideal elastocaloric cooling cycle can harness the decrease in conformation of entropy to increase thermal entropy and heat the bulk material.

In elastomers with strain-induced crystallization, additional latent heat contributed to crystallite formation to heighten the effect. The increased stretchability and uniform chain length distribution of the material increased the theoretical elastocaloric effect, when compared to conventional elastomers. Such elastomers formed strong candidates with suitability for advanced solid-state cooling technologies.

Outlook

In this way, materials scientists Chase M. Hartquist and colleagues compared the deswollen and end-linked star elastomer with natural rubber to show their increased stability, different polymer chemistry, and well-formed structure that combinatorically increased strain-induced crystallization and elastocaloric effect in elastomeric materials. The comparison between the materials revealed their stretchability and chemistry, as well as the significance of the relatively homogenous structure.

Since the early discovery of the rubber band by J.R. Katz in 1924 due to strain-induced crystallization, this biomaterial has played a significant role in society from household goods to car tires. In this report, the team described the next-generation elastomers developed with profound strain-induced crystallization that exceeded the dimensions of natural rubber and other common materials.

The materials developed showed the capacity to outperform conventional counterparts, suggesting the ability to engineer soft materials by regulating their network architecture. These materials play a crucial role to construct futuristic aerospace structures, medical devices and for applications of elastocaloric refrigeration.

More information: Chase M. Hartquist et al, An elastomer with ultrahigh strain-induced crystallization, Science Advances (2023). DOI: 10.1126/sciadv.adj0411

Journal information: Science Advances

© 2023 Science X Network