This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Novel durable copper-aluminum-zinc shape memory alloys for energy-efficient refrigeration

The elastocaloric effect is a phenomenon where a material displays a temperature change when it is exposed to a mechanical stress. The change in temperature occurs due to an entropy difference resulting from a martensitic transformation accompanied by material's crystal structure change under stress.

An analogous effect is observed when the rubber band is stretched: its polymer chains line up in an ordered manner, causing its entropy to decrease. This leads to the rubber band discharging heat to its surroundings and becoming warmer. When the rubber band is released, the opposite occurs, and the rubber band cools down.

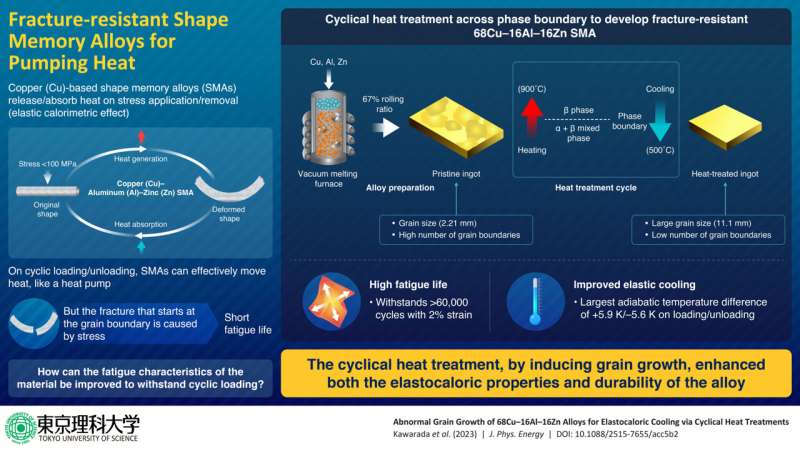

Like rubber bands, metallic superelastic shape memory alloys (SMAs) can also utilize the elastocaloric effect for cooling. Copper (Cu)-based SMAs consisting of Cu, aluminum (Al), and zinc (Zn) are particularly promising due to their low cost and modest stress demands for triggering the temperature lift. However, Cu-Al-Zn SMAs suffer from cyclical fatigue issues as their coarse crystal grains and numerous grain boundaries are susceptible to fracture from repeated expansion and contraction.

Now, in a study published in the Journal of Physics: Energy, Professor Kenjiro Fujimoto from Tokyo University of Science, Professor Ichiro Takeuchi from the University of Maryland, along with researchers from Maryland Energy & Sensor Technologies, have developed a highly durable Cu-Zn-Al SMA capable of withstanding a high number of cyclic loads. "We have been searching for conditions to promote the grain growth of 68Cu-16Al-16Zn alloy to improve its elastocaloric properties," says Prof. Fujimoto, explaining the motivation behind their study.

Recently, they reported that subjecting Cu-Al-Mn alloys to repeated heating and cooling across the mixed and high-temperature phases increased the grain size of the material. Intrigued by these findings, the team decided to investigate whether similar phase transformations could enhance the properties of Cu-Zn-Al alloys.

To prepare the Cu-Al-Zn alloys, the researchers combined Cu, Al, and Zn in a carbon crucible. They melted the metals at low pressures to suppress zinc volatilization. Once the alloy was prepared, the researchers cooled and rolled it into 7 mm thick ingots at three different rolling rates (0%, 67%, and 83%, respectively). The phase boundary temperatures of the alloy were then determined using high-temperature X-ray diffraction, which revealed that the phase boundary between the mixed phase and the high-temperature phase occurred between 700°C and 750°C. Based on this, the researchers repeatedly heated and cooled the alloy between 500°C and 900°C.

All the ingots subjected to the heat treatment cycle showed an increase in crystal grain size, with the maximum increase observed in alloys rolled at a rate of 67%. The grain size of the pristine ingot was 2.21 mm, but the average grain size of the heat-treated ingot in this group increased to 11.1 mm.

"The results indicate that heat treatment across the periodic phase boundary, in addition to the 67 % rolling ratio, is effective for single crystalline-like grain growth," says Prof. Fujimoto. With its larger grains, and fewer grain boundaries, the heat-treated alloy was much more resistant to fracture and was able to withstand more than 60,000 mechanical cycles at 2% strain.

The heat treatment process also resulted in significant improvements in the elastocaloric properties of the Cu-Zn-Al alloy. Compared to previously reported alloys of the same composition, the heat-treated alloy showed latent heat of 6.3 J/g on releasing strain, which is more than double the previously measured value of 2.3 J/g. This indicates that the heat-treated alloy can cool more effectively. Additionally, the alloy exhibited adiabatic temperature difference of +5.9 K and -5.6 K on loading and unloading, respectively, at low cyclic loads (106 MPa).

While rubber band refrigerators have not become mainstream, the elastocaloric effect has the potential to provide innovative cooling solutions. Therefore, developing materials that can achieve this purpose is crucial. In this regard, the heat-treated Cu-Zn-Al alloy exhibits promising properties and can pave the way for efficient and cost-effective cooling systems.

More information: Yuya Kawarada et al, Abnormal grain growth of 68Cu–16Al–16Zn alloys for elastocaloric cooling via cyclical heat treatments, Journal of Physics: Energy (2023). DOI: 10.1088/2515-7655/acc5b2

Provided by Tokyo University of Science