This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

New process 3D prints glass microstructures at low temperature with fast curing

Using ultraviolet light instead of extremely high temperatures, a team of Georgia Tech researchers has developed a new approach for 3D printing small glass lenses and other structures that would be useful for medical devices and research applications.

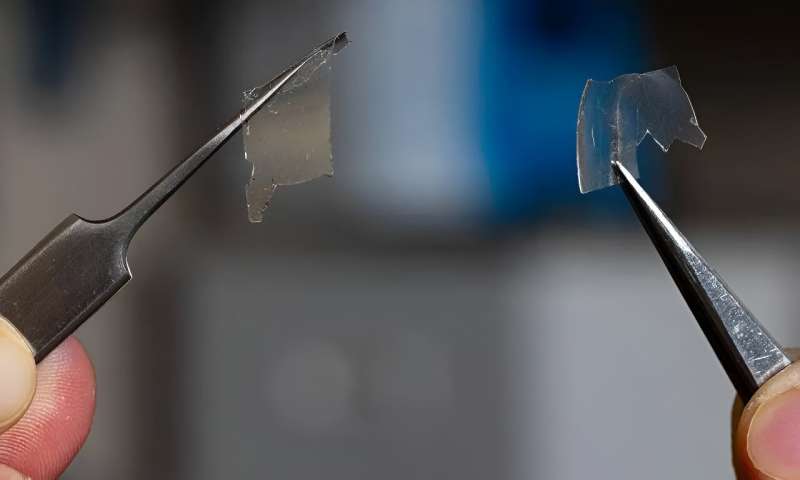

Their process reduces the heat required to convert printed polymer resin to silica glass from 1,100°C to around 220°C and shortens the curing time from 12 hours or more to just five hours. They've used it to produce all kinds of glass microstructures, including tiny lenses approximately the width of a human hair that could be used for medical imaging inside the body.

Led by George W. Woodruff School of Mechanical Engineering Professor H. Jerry Qi, the team described their approach in the journal Science Advances.

"This is one of the exploratory examples showing that it is possible to fabricate ceramics at mild conditions, because silica is a kind of ceramic," Qi said. "It is a very challenging problem. We have a team that includes people from chemistry and materials science engaged in a data-driven approach to push the boundary and see if we can produce more ceramics with this approach."

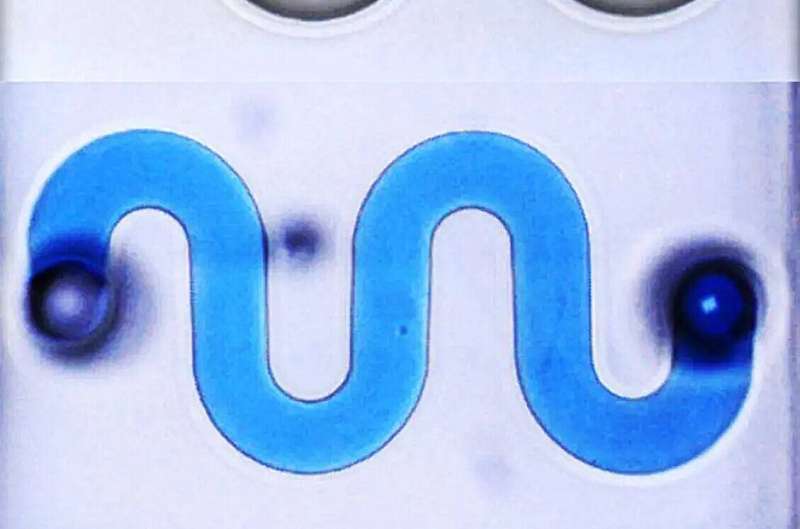

Along with miniaturization of lenses for medical endoscopes, these 3D printed glass structures could create microfluidic devices—typically small computer chip-like devices with nano- or microscale channels used to study cells or biofluids in motion. Glass chips would offer advantages over current chips made of polymer materials, the researchers said, resisting corrosion from chemicals or body fluids.

The low-temperature process also would enable fabrication of microelectronics with glass structures, according to Mingzhe Li, the study's first author.

"We can print in situ, directly into microelectronics," said Li, a postdoctoral researcher in Qi's lab. "Semiconductor materials used in microelectronics cannot withstand very high temperatures. If we want to print directly on a board, we have to do it at a low temperature, and 200°C can definitely do this job."

The team's printing process presents a climate friendlier option for silica glass manufacturing.

Typical additive manufacturing processes for glass require polymer mixtures that must be burned away with heat once the desired shapes are formed. The Georgia Tech team's approach uses a photoresin that is converted to glass using a kind of ultraviolet light called deep UV light. That allows for lower temperatures that save significant heating energy. And because they don't have to add extra polymer material, fewer resources are involved in the first place.

The researchers employed a light-sensitive resin based on a widely used soft polymer called PDMS, and they don't have to add silica nanoparticles to their mix like other 3D printing methods. The result is highly transparent glass without the potential optical issues that can arise with the added nanoparticles. The glass lenses they produced were as smooth as commercially made fused silica glass.

More information: Mingzhe Li et al, Low-temperature 3D printing of transparent silica glass microstructures, Science Advances (2023). DOI: 10.1126/sciadv.adi2958

Journal information: Science Advances

Provided by Georgia Institute of Technology