Tiny sensors, big potential

The electrical energy from batteries powers not only the ignition system that turns the engine and moves electric vehicles but also powers almost every sensing feature of today's automobiles. Electricity turns on the car headlights for night travel, rolls the windows up and down, senses numerous actions within the car to keep drivers aware and alert to their environment.

Today's autos come with many sensors – "door ajar," "seatbelt not fastened," "low tire pressure," "engine rpm's," "obstacle proximity," etc. Newer autonomous sensors can even alert the engine to slow down and stop if the driver is inattentive or incapacitated. Each sensor requires just a little bit of energy from the car's battery, but all those little bits add up; and, as the industry begins to focus more on electric vehicles, networked vehicles, and passenger infotainment features, the number of sensors may increase significantly.

To deal with the problem of battery depletion, UF Engineers have developed a new type of sensor that creates its own energy, extending battery life of automobiles. Dr. Jennifer Andrew, Associate Professor in the Department of Materials Science & Engineering at the University of Florida's Herbert Wertheim College of Engineering, and her team have tackled the challenge of making sensors ever smaller in size and energy consumption.

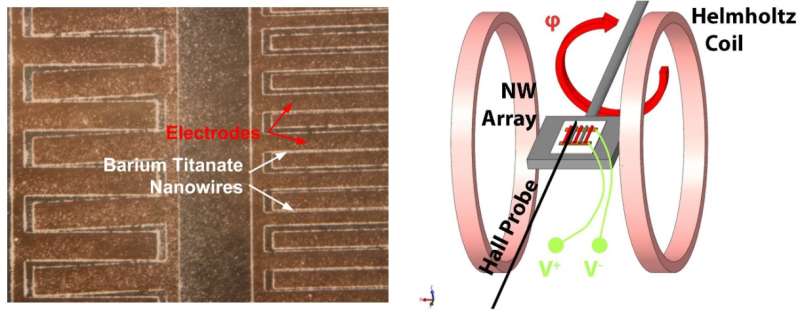

Working with Dr. David Arnold, the George Kirkland Engineering Leadership Professor in the Department of Electrical & Computer Engineering, they have engineered a composite magneto-electric nano-wire array sensor that monitors automobile operations through electrical impulses generated by changing properties of the nano-wire itself. The sensor requires no external electric current at all to operate.

Each nanowire is made up of two halves – barium titanate, which exhibits piezoelectric properties, is paired with cobalt ferrite, a magnetostrictive material. In the presence of a magnetic field, such as the one present in the steel gears in a car engine, the cobalt ferrite undergoes a shape change, which imparts a strain to the piezoelectric barium titanate, thereby inducing an electrical polarization. By connecting the nano-wire array to a data-gathering source, the electrical impulses generated by the magneto-electric can be used to sense the engine timing or detect a skid by the wheel speed. Functional magnetic field sensors are formed by connecting many nanowires in parallel.

Dr. Andrew's group reported that their nano-wires showed significantly stronger magneto-electric coefficients (indicating stronger electrical impulses were generated) than traditional magneto-electric material. These stronger electrical impulses mean that additional improvements to Dr. Andrew's device could result in even smaller sensors. The fact that the sensors use no external electrical energy source adds to their appeal for use in driver-attended and autonomous electrical vehicles.

Provided by University of Florida