3-D-printed live cells convert glucose to ethanol, carbon dioxide to enhance catalytic efficiency

Lawrence Livermore National Laboratory (LLNL) researchers have 3-D printed live cells that convert glucose to ethanol and carbon dioxide gas (CO2), a substance that resembles beer, demonstrating a technology that can lead to high biocatalytic efficiency.

Bioprinting living mammalian cells into complex 3-D scaffolds has been widely studied and demonstrated for applications ranging from tissue regeneration to drug discovery to clinical implementation. In addition to mammalian cells, there is a growing interest in printing functional microbes as biocatalysts.

Microbes are extensively used in industry to convert carbon sources into valuable end-product chemicals that have applications in the food industry, biofuel production, waste treatment and bioremediation. Using live microbes instead of inorganic catalysts has advantages of mild reaction conditions, self-regeneration, low cost and catalytic specificity.

The new research, which appears as an ACS Editors' Choice article in the journal Nano Letters, shows that the additive manufacturing of live whole-cells can assist in research in microbial behaviors, communication, interaction with the microenvironment and for new bioreactors with high volumetric productivity.

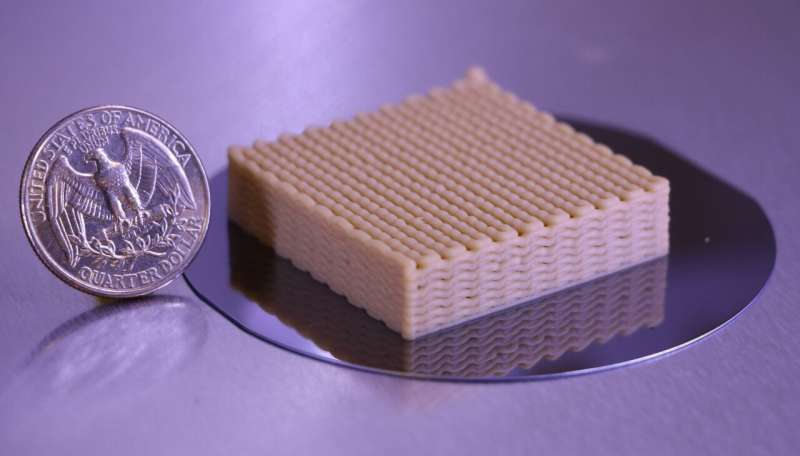

In a case study, the team printed freeze-dried live biocatalytic yeast cells (Saccharomyces cerevisiae) into porous 3-D structures. The unique engineered geometries allowed the cells to convert glucose to ethanol and CO2 very efficiently and similar to how yeast on its own can be used to make beer. Enabled by this new bio-ink material, the printed structures are self-supporting, with high resolution, tunable cell densities, large scale, high catalytic activity and long-term viability. More importantly, if genetically modified yeast cells are used, high-valuable pharmaceuticals, chemicals, food and biofuels can be produced as well.

"Compared to bulk film counterparts, printed lattices with thin filament and macro-pores allowed us to achieve rapid mass-transfer leading to several-fold increase in ethanol production," said LLNL materials scientist Fang Qian, the lead and corresponding author on the paper. "Our ink system can be applied to a variety of other catalytic microbes to address broad application needs. The bioprinted 3-D geometries developed in this work could serve as a versatile platform for process intensification of an array of bioconversion processes using diverse microbial biocatalysts for production of high-value products or bioremediation applications."

Other Livermore researchers include Cheng Zhu, Jennifer Knipe, Samantha Ruelas, Joshua Stolaroff, Joshua DeOtte, Eric Duoss, Christopher Spadaccini and Sarah Baker. This work was conducted in collaboration with National Renewable Energy Laboratory.

"There are several benefits to immobilizing biocatalysts, including allowing continuous conversion processes and simplifying product purification," said chemist Baker, the other corresponding author on the paper. "This technology gives control over cell density, placement and structure in a living material. The ability to tune these properties can be used to improve production rates and yields. Furthermore, materials containing such high cell densities may take on new, unexplored beneficial properties because the cells comprise a large fraction of the materials."

"This is the first demonstration for 3-D printing immobilized live cells to create chemical reactors," said engineer Duoss, a co-author on the paper. "This approach promises to make ethanol production faster, cheaper, cleaner and more efficient. Now we are extending the concept by exploring other reactions, including combining printed microbes with more traditional chemical reactors to create 'hybrid' or 'tandem' systems that unlock new possibilities."

More information: Fang Qian et al. Direct Writing of Tunable Living Inks for Bioprocess Intensification, Nano Letters (2019). DOI: 10.1021/acs.nanolett.9b00066

Journal information: Nano Letters

Provided by Lawrence Livermore National Laboratory