Green production of chemicals for industry

Industry consumes large quantities of crude oil to produce basic substances for drugs, cosmetics, plastics, or food. However, these processes consume a lot of energy and produce waste. Biological processes with enzymes are far more sustainable. The protein molecules can catalyze various chemical reactions without auxiliary materials or solvents being required. But they are expensive and, hence, have been economically unattractive so far. Researchers of Karlsruhe Institute of Technology (KIT) have now developed a new biomaterial that considerably facilitates the use of enzymes. The results are presented in the journal Angewandte Chemie.

Catalysts ensure rapid reaction of basic substances to the end product desired with low energy consumption. Hence, they are of high significance to chemical industry. In about 90 percent of all chemical processes, catalysts are applied. Scientists of KIT have now developed an environmentally friendly alternative biomaterial, the use of which is associated with reduced energy consumption. "In the long term, such biocatalytic materials are to be used in automatic production of value-added basic compounds without complex synthesis and cleaning steps and with a minimum amount of waste arising," says Professor Christof Niemeyer of KIT's Institute for Biological Interfaces.

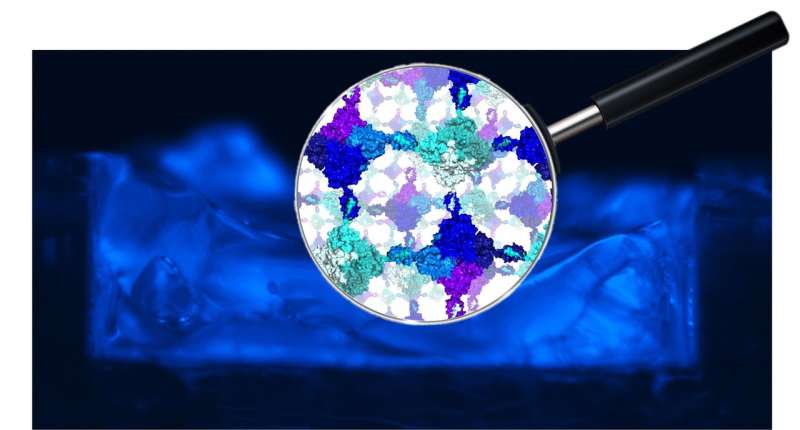

For this purpose, scientists modified natural enzymes such that they self-assemble in a stable biocatalyst. Similar to a two-component adhesive, the enzymes form a gel-type material. This material is applied onto plastic chips with groove-shaped depressions. Drying leads to concentration and formation of the hydrogel. Then, this chip is covered by a plastic foil and basic substances can be pumped through the grooves and are converted into the final products desired by the biocatalysts. The biocatalyst gel remains. No solvents or high temperatures and pressures are needed, which makes the process highly sustainable and environmentally compatible.

As a large reaction volume exists on smallest space, conversion rates in such miniaturized flow reactors or small reaction vessels are very high. Their use in biocatalytic processes, however, is still in its infancy, as carrier materials have been required so far to fix the enzymes in the reactor. These carriers need reactor space that then is no longer available for the biocatalyst. The new biomaterial, by contrast, adheres to the carrier and the reactor can be filled with a maximum amount of biocatalyst. Moreover, it can be recycled completely, is biodegradable, highly stable, and reaches extremely high yields in reactions, for which expensive auxiliary materials are required.

Compared to chemical materials, biocatalysts are particularly advantageous when so-called enantiomers are produced by a process. These are compounds that are mirror images of each other. As a rule, only one of the compounds is needed for the reaction, the second may even have undesired effects. With the help of biocatalysts, specific production of one of both compounds is possible, whereas chemical processes often require expensive auxiliary materials for this purpose or separation of the undesired compound.

Work was carried out within the framework of the Helmholtz Program "BioInterfaces in Technology and Medicine" (BIFTM). "Our research and development work was possible only with the equipment and infrastructure of this program," says Christof Niemeyer. Within the framework of this program, scientists of KIT cooperate across disciplines to study and use biological systems for later application in the industrial and medical bioengineering sectors. High interdisciplinarity requires broad methodological expertise covering materials production and characterization as well as data-based simulation methods. This know-how is available at KIT.

More information: Theo Peschke et al, Self-Assembling All-Enzyme Hydrogels for Flow Biocatalysis, Angewandte Chemie (2018). DOI: 10.1002/ange.201810331

Journal information: Angewandte Chemie

Provided by Karlsruhe Institute of Technology