Quick and not-so-dirty: A rapid nano-filter for clean water

Australian researchers have designed a rapid nano-filter that can clean dirty water over 100 times faster than current technology.

Simple to make and simple to scale up, the technology harnesses naturally occurring nano-structures that grow on liquid metals.

The RMIT University and University of New South Wales (UNSW) researchers behind the innovation have shown it can filter both heavy metals and oils from water at extraordinary speed.

RMIT researcher Dr. Ali Zavabeti said water contamination remains a significant challenge globally—1 in 9 people have no clean water close to home.

"Heavy metal contamination causes serious health problems and children are particularly vulnerable," Zavabeti said.

"Our new nano-filter is sustainable, environmentally-friendly, scalable and low cost.

"We've shown it works to remove lead and oil from water but we also know it has potential to target other common contaminants.

"Previous research has already shown the materials we used are effective in absorbing contaminants like mercury, sulfates and phosphates.

"With further development and commercial support, this new nano-filter could be a cheap and ultra-fast solution to the problem of dirty water."

The liquid metal chemistry process developed by the researchers has potential applications across a range of industries including electronics, membranes, optics and catalysis.

"The technique is potentially of significant industrial value, since it can be readily upscaled, the liquid metal can be reused, and the process requires only short reaction times and low temperatures," Zavabeti said.

Project leader Professor Kourosh Kalantar-zadeh, Honorary Professor at RMIT, Australian Research Council Laureate Fellow and Professor of Chemical Engineering at UNSW, said the liquid metal chemistry used in the process enabled differently shaped nano-structures to be grown, either as the atomically thin sheets used for the nano-filter or as nano-fibrous structures.

"Growing these materials conventionally is power intensive, requires high temperatures, extensive processing times and uses toxic metals. Liquid metal chemistry avoids all these issues so it's an outstanding alternative."

How it works

The groundbreaking technology is sustainable, environmentally-friendly, scalable and low-cost.

The researchers created an alloy by combining gallium-based liquid metals with aluminium.

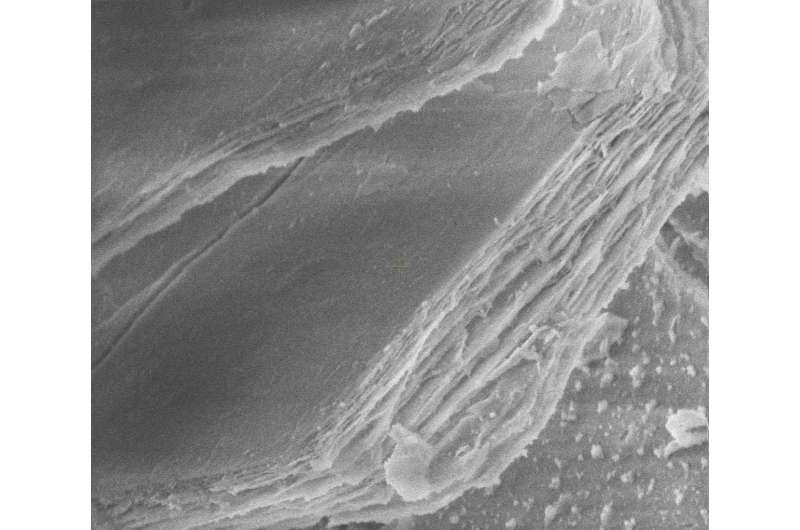

When this alloy is exposed to water, nano-thin sheets of aluminium oxide compounds grow naturally on the surface.

These atomically thin layers—100,000 times thinner than a human hair—restack in a wrinkled fashion, making them highly porous.

This enables water to pass through rapidly while the aluminium oxide compounds absorbs the contaminants.

Experiments showed the nano-filter made of stacked atomically thin sheets was efficient at removing lead from water that had been contaminated at over 13 times safe drinking levels, and was highly effective in separating oil from water.

The process generates no waste and requires just aluminium and water, with the liquid metals reused for each new batch of nano-structures.

The method developed by the researchers can be used to grow nano-structured materials as ultra-thin sheets and also as nano-fibres.

These different shapes have different characteristics—the ultra-thin sheets used in the nano-filter experiments have high mechanical stiffness, while the nano-fibres are highly translucent.

The ability to grow materials with different characteristics offers opportunities to tailor the shapes to enhance their different properties for applications in electronics, membranes, optics and catalysis.

The research is funded by the Australian Research Council Centre for Future Low-Energy Electronics Technologies (FLEET).

The findings are published in the journal Advanced Functional Materials.

More information: Advanced Functional Materials (2018). DOI: 10.1002/adfm.201804057

Journal information: Advanced Functional Materials

Provided by RMIT University