Environmentally friendly and efficient propane heat pump

Heat pumps use environmental energy to provide us with heat. However, they generally require synthetic refrigerants, which contain environmentally harmful fluorinated greenhouse gases (F-gases). Fraunhofer researchers have now contributed to the development of a heat pump that uses propane instead. The pump is both more climate-friendly and more efficient.

"Heating and hot water account for around 40 percent of Germany's final energy consumption. Burning high-quality fossil fuels such as natural gas or crude oil not only makes little sense energetically, it also harms the climate. Each unit of electrical energy required to operate a heat pump, derived often from renewable resources, generates three to five units of CO2-neutral heat energy. This makes heat pumps an important element in implementing Germany's transition to a sustainable energy system," says Dr. Marek Miara, who coordinates work on heat pumps at the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg.

A heat pump works in a similar fashion to a fridge. The refrigerant absorbs the heat inside the fridge and transports it outside. The difference is that heat left to escape freely from the back of a fridge is what a heat pump extracts – in this case from the ground, groundwater, or ambient air – to heat our homes or water.

To achieve this, the heated, vaporized refrigerant is compressed, which raises its temperature and pressure. The hot refrigerant gas releases its heat into water and condenses. The warm water flows into underfloor heating systems, radiators or hot water storage tanks, while the liquid refrigerant, now cool, flows back into a so-called evaporator, where it once again absorbs heat energy. The cycle then starts again from the beginning.

For the most part, refrigerants are composed of a mixture of synthetic substances containing environmentally harmful, fluorinated greenhouse gases (F-gases). In June 2014, the European Commission announced that F-gases are to be phased out of the market. One environmentally friendly, natural alternative to synthetic refrigerants is propane, which is already gaining in popularity in air conditioning and refrigeration systems. But its use in heat pumps is still relatively new.

Because even though propane has excellent thermodynamic properties, it is highly flammable, and this poses a challenge when used in a heat cycle.

"If you want to use propane, you have to keep the volume of refrigerant as low as possible to minimize the risks involved," says Dr. Lena Schnabel, who heads the department for heating and cooling technologies at Fraunhofer ISE.

A bionic structure ensures even distribution

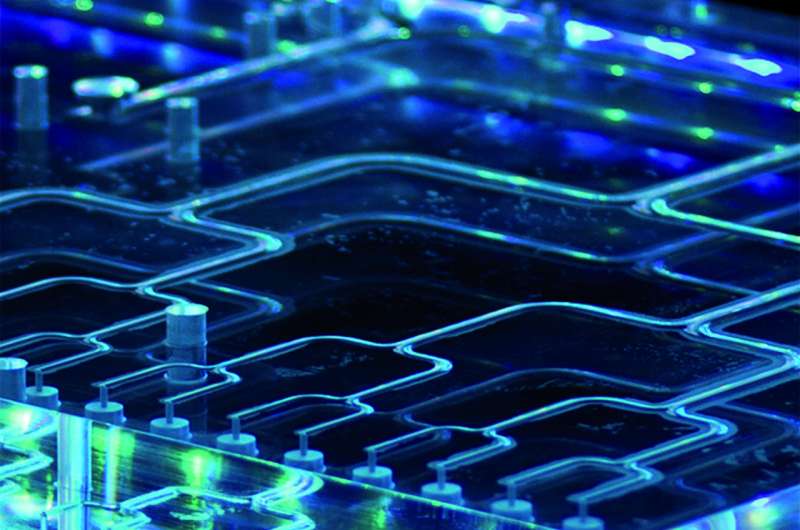

The solution of the ISE researchers, along with their European research partners, is to employ highly compact, brazed, finned heat exchangers that function well with small volumes of liquid. The thermal energy is transferred from one flowing substance to the other via heat exchangers. These are composed of numerous parallel channels containing the circulating refrigerant, which either absorb heat (known as "vaporizers") or radiate it ("condensers"). "The liquid should completely vaporize or recondense over the running length. To guarantee they operate efficiently, the vapor-liquid ratio must be identical in all the channels. Generally, that's not easy to achieve, and it becomes especially tricky if you're also trying to limit the volume of refrigerant."

To solve the problem, Schnabel and her team developed a distributor with a bionic structure: "Conventional Venturi distributors look like a pile of spaghetti made of many thin tubes that merge where they meet the vaporizer. Our distributor is different: it has a continuously branching structure like the branches and twigs of a tree, which ensure even distribution of the refrigerant into the individual evaporator channels, even with a small volume of refrigerant." This structure allows optimal use of the entire surface of the heat exchanger, which improves efficiency.

To reduce the risk of explosion when compressing the propane, Schnabel and her team used a specialized compressor in which all ignition sources were encapsulated. They took great care connecting the individual components of the pump to prevent propane from escaping. "We are currently modifying the technical design of the heat pump, testing the long-term behavior of its components, and developing sustainable safety strategies," says Schnabel.

Provided by Fraunhofer-Gesellschaft