Smart ink adds new dimensions to 3-D printing

Researchers at Dartmouth College have developed a smart ink that turns 3D-printed structures into objects that can change shape and color. The innovation promises to add even more functionality to 3D printing and could pave the way to a new generation of printed material.

The advancement in the area of form-changing intelligent printing - also known as 4D printing - provides a low-cost alternative to printing precision parts for uses in areas ranging from biomedicine to the energy industry.

"This technique gives life to 3D-printed objects," said Chenfeng Ke, an assistant professor of chemistry at Dartmouth. "While many 3D-printed structures are just shapes that don't reflect the molecular properties of the material, these inks bring functional molecules to the 3D printing world. We can now print smart objects for a variety of uses."

Many 3D printing protocols rely on photo-curing resins and result in hard plastic objects with rigid, but random molecular architectures. The new process allows designers to retain specific molecular alignments and functions in a material and converts those structures for use in 3D printing.

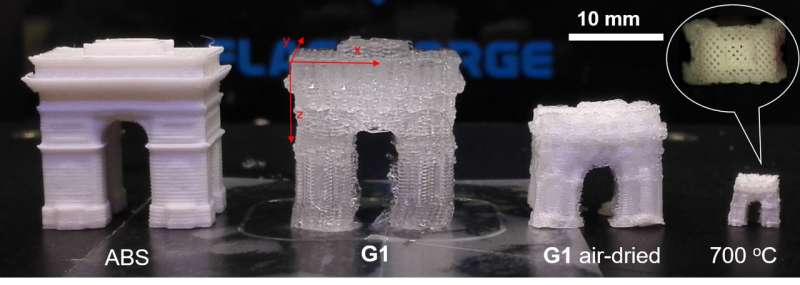

By using a combination of new techniques in the pre-printing and post-printing processes, researchers were able to reduce printed objects to 1 percent of their original sizes and with 10-times the resolution. The 3D printed objects can even be animated to repeatedly expand and contract in size through the use of supramolecular pillars. With fluorescent trackers, the objects can be made to change color in response to an external stimulus such as light.

The ability to reduce the size of an object after printing while preserving functional features and increasing resolution allows inexpensive printers to print high-resolution objects that were once only possible with much more sophisticated printers.

According to the study, which was selected as a VIP paper by Angewandte Chemie, the journal of the German Chemical Society, the smart ink can print at a rough, 300-micron resolution, but the end product would feature a much finer line width of 30 microns.

"This process can use a $1,000 printer to print what used to require a $100,000 printer," said Ke. "This technique is scalable, widely adaptable and can dramatically reduce costs."

To create the smart ink, researchers used a polymer-based "vehicle" that integrates intelligent molecular systems into printing gel and allows for the transformation of their functions from the nanosacle to the macroscale.

While most materials are readily hardened during the 3D printing process, the new process introduces a series of post-printing reactions which lock the active ingredients together and retain the form of the molecular structure throughout the printing process.

The result is a printed object with a molecular design that is programmed to transform itself: If you provide it with chemical fuel, it changes shape. If you shine a light on it, it can change color.

"This is something we've never seen before. Not only can we 3D print objects, we can tell the molecules in those objects to rearrange themselves at a level that is viewable by the naked eye after printing. This development could unleash the great potential for the development of smart materials," Ke said.

While researchers believe the technology is still far away from intelligent 3D systems that can dynamically change their configuration, current uses for the technology could be to print precision filters and storage devices. Over time, researchers expect that the process could result in a new class of macroscale 3D printed objects that can be used to deliver medicine or produce high resolution bone replacements.

According to the research team involved in the study: "We believe this new approach will initiate the development of small molecule-based 3D printing materials and greatly accelerate the development of smart materials and devices beyond our current grasp that are capable of doing complex tasks in response to environmental stimuli."

In the immediate term, researchers expect the smart inks to be useful to materials chemists, 3D printing engineers and others interested in bringing functional materials into 3D printing.

More information: Longyu Li et al, Hierarchical Co-Assembly Enhanced Direct Ink Writing, Angewandte Chemie International Edition (2018). DOI: 10.1002/anie.201800593

Journal information: Angewandte Chemie , Angewandte Chemie International Edition

Provided by Dartmouth College