3D-printed aerogels improve energy storage

A new type of graphene aerogel will make for better energy storage, sensors, nanoelectronics, catalysis and separations.

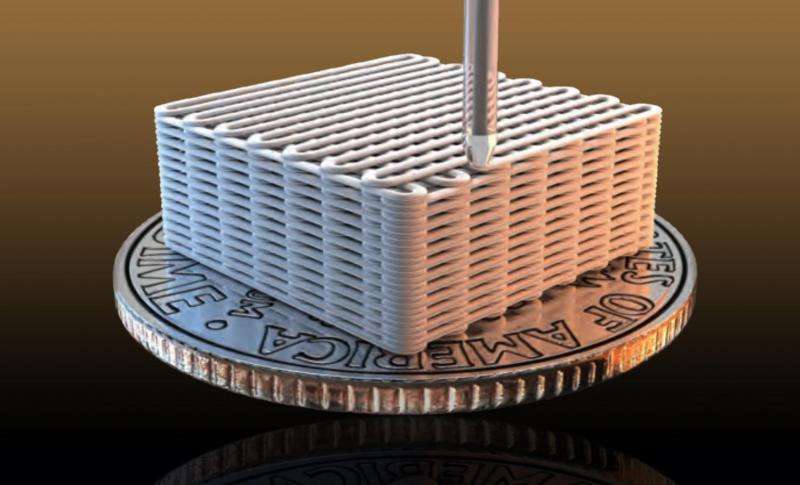

Lawrence Livermore National Laboratory researchers have made graphene aerogel microlattices with an engineered architecture via a 3D printing technique known as direct ink writing. The research appears in the April 22 edition of the journal, Nature Communications.

The 3D printed graphene aerogels have high surface area, excellent electrical conductivity, are lightweight, have mechanical stiffness and exhibit supercompressibility (up to 90 percent compressive strain). In addition, the 3D printed graphene aerogel microlattices show an order of magnitude improvement over bulk graphene materials and much better mass transport.

Aerogel is a synthetic porous, ultralight material derived from a gel, in which the liquid component of the gel has been replaced with a gas. It is often referred to as "liquid smoke."

Previous attempts at creating bulk graphene aerogels produce a largely random pore structure, excluding the ability to tailor transport and other mechanical properties of the material for specific applications such as separations, flow batteries and pressure sensors.

"Making graphene aerogels with tailored macro-architectures for specific applications with a controllable and scalable assembly method remains a significant challenge that we were able to tackle," said engineer Marcus Worsley, a co-author of the paper. "3D printing allows one to intelligently design the pore structure of the aerogel, permitting control over mass transport (aerogels typically require high pressure gradients to drive mass transport through them due to small, tortuous pore structure) and optimization of physical properties, such as stiffness. This development should open up the design space for using aerogels in novel and creative applications."

During the process, the graphene oxide (GO) inks are prepared by combining an aqueous GO suspension and silica filler to form a homogenous, highly viscous ink. These GO inks are then loaded into a syringe barrel and extruded through a micronozzle to pattern 3D structures.

"Adapting the 3D printing technique to aerogels makes it possible to fabricate countless complex aerogel architectures for a broad range of applications including its mechanical properties and compressibility, which has never been achieved before, " said engineer Cheng Zhu, the other co-author of the journal article.

Journal information: Nature Communications

Provided by Lawrence Livermore National Laboratory