Electricity from a thin film

Teams of researchers all over the world are working on the development of organic solar cells. The Fraunhofer Institute for Solar Energy Systems ISE in Freiburg is presenting avenues towards industrial mass production at the world’s largest trade fair for nanotechnology, the nano tech 2008 from February 21 through 23 in Tokyo.

Organic solar cells have good prospects for the future: They can be laid onto thin films, which makes them cheap to produce. Established printing technologies should be employed for their production of the future. In order to achieve this goal of suitable solar cell architecture as well a coating materials and substrates have to be developed. “This method permits a high throughput, so the greatest cost is that of materials,” says Michael Niggemann, a researcher at ISE.

Nevertheless, organic solar cells are not intended to compete with classic silicon cells – they are not nearly efficient enough to do that just yet. Because they are flexible, however, they can open up new fields of application: Plastic solar cells could supply the power for small mobile devices such as MP3 players or electronic ski passes. Another possibility would be to combine solar cells, sensors and electronic circuits on a small strip of plastic to form a self-sufficient power microsystem.

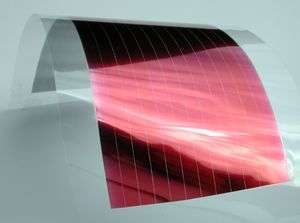

At nano tech in Tokyo, the Fraunhofer experts will be presenting a flexible solar module that is as small as the page of a book. It was produced by a method that can easily be transferred to roll-to-roll technology – a vital step en route to mass production.

A new design principle helps to save costs, too: Until now, the front electrode, the one that faces the sun, has usually been made of expensive indium tin oxide because this material is transparent. But now there is an alternative: The Fraunhofer crew has interconnected a poorly conductive transparent polymer electrode with a highly conductive metal layer on the rear side of the solar cell. This connection is done trough numerous tiny holes in the solar cell .This has the advantage that a low-priced material can be used. The idea has already been patented.

Source: Fraunhofer-Gesellschaft