Diamagnetic levitation of pyrolitic graphite over a single magnet achieved

Diamagnetic levitation of pyrolitic graphite over a single magnet has been achieved, using commercially available magnetic field domain printing technology. Using this approach, levitation applications, including bearings and sensors, could be realised without the use of complex magnet arrays.

Intrinsic reaction

In diamagnetism, a material creates a repelling magnetic field in reaction to an applied magnetic field. The strength of the effect is highly material-dependent; in diamagnetic materials it is the dominant form of magnetism and can be strong enough to allow levitation of some materials, including water, bismuth and graphite.

The repelling magnetic field, produced by a modification of the orbits of the electrons in the diamagnetic material, allows levitation that does not need energy input, nor feedback control, and so is of interest for applications including bearings and MEMS sensor systems. Recent research has included its use in a levitated flywheel battery and nanoforce sensors.

Typically, an array of magnets arranged in a chessboard pattern of alternating magnetisation directions is used to achieve stable diamagnetic levitation. This pattern creates the necessary strong magnetic field and field gradient. Such arrays take time to assemble and the brittle NdFeB magnets often used can be damaged in the assembly process. Before assembly, each magnet needs to be machined, magnetised and coated individually, making array manufacture time-consuming and costly.

Printed patterns

In this issue of Electronics Letters, Gerald Küstler, an independent researcher based in Germany, reports the use of an existing, commercially available magnet production technology to eliminate the need for a magnet array in diamagnetic levitation.

"I recognised that magnets with printed magnetic field domains can be used to realise diamagnetic levitation over a single magnet," explains Küstler. "The technology of printing magnetic field domains was just recently developed by Correlated Magnets Research LLC. Their aim is to provide magnets with very specific and improved properties and behaviour. However, as far as I know, diamagnetic levitation applications were never in their focus."

Normal magnetisation technologies use a set of magnetisation coils arranged to achieve a single specific magnetisation pattern. This allows simple magnetisation patterns like linear or radial opposite patterns to be made, for example, the alternating parallel rows of magnetisation of a fridge magnet.

More complex patterns with undisturbed closed loops, such as an opposite, nested ring pattern, can't be made this way, as there must always be an access for the current feeding wires at one point of the loop. Building a custom magnetisation coil for a new specific field pattern also means a significant investment of money and time.

The process adopted by Correlated Magnetics Research LLC uses an impulse magnetiser and a linear stage which moves a small magnetisation coil above the surface of the magnet to be magnetised. In this way, the necessary, detailed, magnetic field domain pattern can be built up step by step.

Using this technology, Küstler was able to obtain the necessary pattern to achieve diamagnetic levitation using a single magnet, eliminating the costs and complexities of array manufacture. He expects that this approach to creating magnetisation patterns will provide researchers in diamagnetic levitation with much more flexibility, making it possible to create and test different patterns quickly, and accelerate the research and development process:

"Researchers will be able to print magnetic field patterns needed for diamagnetic levitation tracks, bearings or sensors with a free floating seismic mass. Field pattern design and printing could be iteratively adapted to specific requirements in a matter of minutes. So, in the short-term, I would see a benefit in cut-down development times and in the long-term, it would be imaginable that such monolithic magnets for diamagnetic levitation will be mass produced."

A strong future

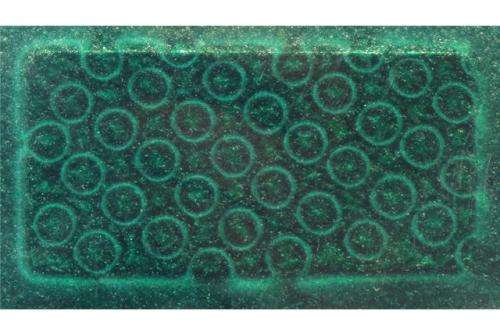

Küstler has since been investigating single magnet diamagnetic levitation using different multipole magnetisation patterns and has demonstrated levitation of multiple objects at the same time (see main image).

He has also investigated the levitation of a 25 µm thin graphene sheet, which suggests another possible long term application. "From the literature, it is known that by heating up a diamagnetic sheet partly with a laser beam, it can be moved over the surface of a magnet array. So, by combining the most recent developments in this field, it is possible to imagine a monolithic multipole magnet where one can move tiny sheets of graphene using lasers. That would be a step in the direction of micro-robots. Approaches in this field were also reported recently," says Küstler.

"Lab-on-chips would be another long-term topic. Personally, I'm keen to see the development of much stronger permanent magnets than we already have. Nanocomposite magnets or iron nitride magnets are already in development and promise an enormous increase in energy density compared to state-of-the-art NdFeB magnets. With such magnets, the levitation height and load bearing capacity in diamagnetic levitation applications could be significantly increased."

More information: "Diamagnetic levitation of pyrolytic graphite over monolithic NdFeB magnet." G. Küstler Electronics Letters, Volume 50, Issue 18, 28 August 2014, p. 1289 – 1290. DOI: 10.1049/el.2014.2332 , Print ISSN 0013-5194, Online ISSN 1350-911X

Journal information: Electronics Letters

Provided by Institution of Engineering and Technology

This story is published courtesy of Electronics Letters. For additional Electronics Letters news and features visit theiet.org/eletters.