Environmentally compatible organic solar cells

Environmentally compatible production methods for organic solar cells from novel materials are in the focus of "MatHero". The new project coordinated by Karlsruhe Institute of Technology (KIT) aims at making organic photovoltaics competitive to their inorganic counterparts by enhancing the efficiency of organic solar cells, reducing their production costs and increasing their life-time. "Green" processes for materials synthesis and coating play a key role. "MatHero" is funded by the European Commission with an amount of EUR 3.5 million.

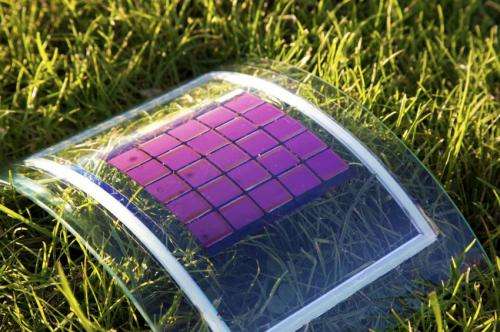

Organic solar cells will open up entirely new markets for photovoltaics. These "plastic solar cells" have several advantages: They are light-weight, mechanically flexible, can be produced in arbitrary colors, and hence allow a customized design for a variety of applications. Moreover, organic solar cells can be produced by printing processes with a low consumption of materials and energy, enabling the inexpensive production of high numbers of solar cells. In order to become competitive in established markets, various challenges still have to be mastered. The energy conversion efficiency has to be improved to more than ten percent. Costs of materials synthesis have to be reduced. The life-time of the materials and modules has to be enhanced to more than ten years.

To reach these objectives, the European project consortium of "MatHero" studies environmentally compatible processes for materials synthesis, coating and printing. All novel printable materials are formulated using non-chlorinated solvents. "The use of environmentally compatible solvents is a major prerequisite for cost reduction, as complex safety measures on the industrial scale will no longer be required," Dr. Alexander Colsmann of KIT's Light Technology Institute (LTI) explains. Together with Christian Sprau, Colsmann coordinates the project.

"MatHero – New materials for highly efficient and reliable organic solar cells" covers the complete value chain of organic solar cell fabrication: From the design and synthesis of the polymers used to assemble the solar cells to the fabrication and characterization of the modules to the assessment of device stability. The project goal is an environmentally compatible printed organic solar module initially for off-grid applications. In the consortium, physicists, chemists, materials scientists, and engineers cooperate in an interdisciplinary project team in order to study fundamental scientific and product development aspects. The KIT scientists develop new solar cell architectures and analyze process up-scaling, focusing on enhancing solar cell efficiencies as well as on using environmentally compatible solvents.

"MatHero" is funded by the EC under the 7th framework programme with an amount of EUR 3.5 million. Besides KIT, the research institutions Fraunhofer Institute for Applied Polymer Research (IAP), Potsdam, the Commissariat à l'Énergie Atomique et aux Énergies Alternatives (CEA) in France, and Acondicionamiento Tarrasense (LEITAT) in Spain participating in the project. The industry partners are Advent Technologies SA (Greece), and Arkema (France) and Eight19 Ltd (UK). The project started in early 2014 and is scheduled for a duration of three years.

Provided by Helmholtz Association of German Research Centres