Researchers work to make solar tech more affordable

(Phys.org)—SLAC's Stanford Synchrotron Radiation Lightsource will play a central role in three research projects that seek cheaper materials and manufacturing techniques for solar panels, with support from a Department of Energy program called the SunShot Initiative.

The studies are aimed at improving an ink jet-like printing technique for producing flexible solar paneling, making thin-film solar panels more efficient and understanding structural changes in solar panel components that are heated during manufacturing.

Each project will run for three years, said Mike Toney, who leads the SSRL Materials Science Division and will participate in two of the projects.

"These are challenging experiments. One of the reasons they haven't been done before is that they're not easy," Toney said. He said he expects the research to begin soon.

Building experimental chambers for performing X-ray analyses of the solar materials and processing techniques will involve many scientific disciplines, Toney noted, from physics to chemistry to materials science and chemical engineering. "That's one of the things that make it fun," he said.

Toney said he would have been delighted to receive DOE support for even one of the three submitted proposals. "We got all three, which was pretty surprising to me," Toney said. "They are good opportunities to demonstrate how SSRL and DOE labs in general can participate in work that's more applied."

Toney and Stefan Mannsfeld, an SSRL materials science researcher, had earlier received a Laboratory Directed Research and Development grant from SLAC to conduct research on printing processes for producing solar panel layers, and Toney said he believes that research played a role in securing the SunShot support.

More about the new research:

Printing Layers for Flexible Solar Panels

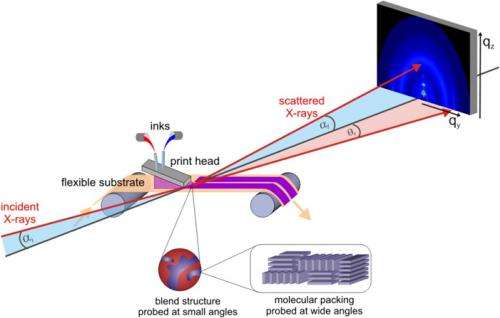

Flexible solar panels, made from plastics or similar materials, are a cheap alternative to conventional silicon-based panels. But today's flexible panels are several times less efficient than conventional panels. A low-cost printing technique using solar panel materials as ink could be the solution to lowering the cost and possibly improving the performance of flexible panels.

Mannsfeld and Toney, along with researchers Zhenan Bao of Stanford University and Paulette Clancy of Cornell University, will study the nanoscale details of this printing process, with a goal of improving the technique and boosting the panels' efficiency. This project, which uses an X-ray analysis technique known as scattering, is slated to receive $878,578 over three years.

New Materials for Solar Panel Layer

Studying how electrons travel throughout the layers in a solar panel – from the top or "emitter" layer to the base or "bulk" light-absorbing material – could lead to improvements in design, including the development of new top-layer materials that let light through more efficiently. A goal of this project, which has been approved for $896,250 over three years, is a 2 percent gain in efficiency for thin-film solar panels and solar cells with greater than 20.3 percent efficiency.

A research team led by the National Renewable Energy Laboratory in Colorado, including SLAC scientists Dennis Nordlund, Tsu-Chien Weng and Apurva Mehta, will use X-ray spectroscopy and diffraction techniques at SSRL to study emitter-layer materials.

Studying Heat Treatment on Solar Panel Components

The manufacturing of some solar panels incorporates rapid heating. But little is known about structural changes to the materials during heating. The experiments will study how heat affects layered materials and other components, with a goal of improving the processing and creat more efficient solar cells. Samples will be rapidly heated to about 1,000 to 2,000 degrees Fahrenheit, with data collected in hundredths-of-a-second intervals.

Provided by SLAC National Accelerator Laboratory