This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Study unveils strategy for improving mechanical properties of aluminum composites

Particle-reinforced aluminum matrix composites (PRAMCs), in which the aluminum matrix is reinforced with nanoparticles, exhibit great potential for applications in the aerospace and automobile industries. These materials combine the advantages of both aluminum matrix and reinforcement particles, including high specific strength, high specific modulus, and good wear resistance.

Consequently, PRAMCs are regarded as the most promising and economical materials to improve energy efficiency and reduce emissions in the automotive and aerospace industries. However, the tradeoff between the strength and ductility of PRAMCs severely limits their application.

To address this long-standing challenge, a team of researchers from China, led by Professor Jin-feng Nie and Professor Yong-hao Zhao from the Nano and Heterogeneous Materials Center at the School of Materials Science and Engineering at Nanjing University of Science and Technology developed a new strategy to improve the strength and ductility synergy of PRAMCs. Their findings were made available online on May 2 2024 and published in Transactions of Nonferrous Metals Society of China.

Explaining the motivation behind their study, Prof. Zhao says, "Studies have shown that the spatial configuration of reinforcement particles plays a crucial role in enhancing the strength and ductility of PRAMCs. Furthermore, introducing a heterogenous structure in the aluminum matrix, which consists of zones of nanoparticles with dramatically different properties than the bulk, can improve traditional materials' strength and ductility.

"Hence, we developed a strategy for improving the mechanical properties of PRAMCs by introducing a heterogeneous structure and regulating its particle configuration."

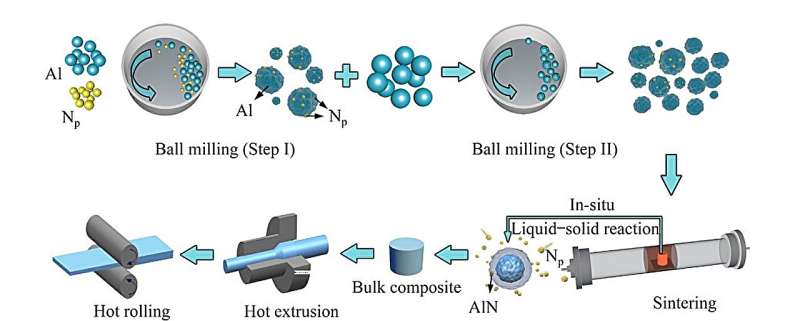

The researchers first fabricated a heterostructured aluminum nitride/aluminum (AlNp/Al) composite using a liquid-solid reaction, followed by hot extrusion. The resulting composite consisted of large clusters of AlNp particles distributed within the Al matrix, which were detrimental to the mechanical properties. To regulate the spatial particle distribution, the researchers subjected the extruded composite to hot rolling.

Dr. Nie explains, "During plastic deformation treatment, such as rolling, high-pressure torsion, etc., large plastic deformation accumulates in materials, which can regulate the heterogeneous microstructure." Hot rolling was carried out at 500 oC with equivalent strains of 0.7–1.4.

Depending on the equivalent strains, three types of composites were formed with different spatial configurations of AlNp. The three composites, termed Clustered-AlNp/Al, Networked-AlNp/Al, and Uniformed-AlNp/Al, exhibited particle distributions as clusters, networks, and uniform dispersion, respectively. On evaluating the mechanical properties of the composites, the researchers found that their properties improved with particle refinement.

Notably, the yield strength and tensile strength of the Uniformed-AlNp/Al composite were found to be 334.6 and 387.4 MPa, which were 55 and 52.9 MPa higher than the Clustered AlNp/Al composite. Moreover, the elongation to failure increased from 6.8% to 9.1%, suggesting an excellent balance of strength and ductility, superior to previously reported aluminum matrix composites.

Furthermore, the researchers determined that the hetero-deformation-induced (HDI) stress, which refers to the stress generated in composite materials due to the different deformation behavior of the constituent materials, played a significant role in enhancing the strength and ductility of the composite. HDI stress was highest in the Uniformed-AlNp/Al composite.

Highlighting the significance of the study, Prof. Zhao says, "Our proposed strategy will provide new insights and guidance for the design of composites with superior strength and ductility combinations."

Overall, the findings of the study can pave the way for the development of novel composite materials that can contribute to reducing emissions and increasing the efficiency of automobiles and airplanes.

More information: Yu-yao CHEN et al, Enhancing strength–ductility synergy of AlNp/Al composite by regulating heterostructure of matrix grain and particle distribution, Transactions of Nonferrous Metals Society of China (2024). DOI: 10.1016/S1003-6326(23)66453-2

Provided by Cactus Communications