This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Transforming common soft magnets into next-generation thermoelectric conversion materials with 3-minute heat treatment

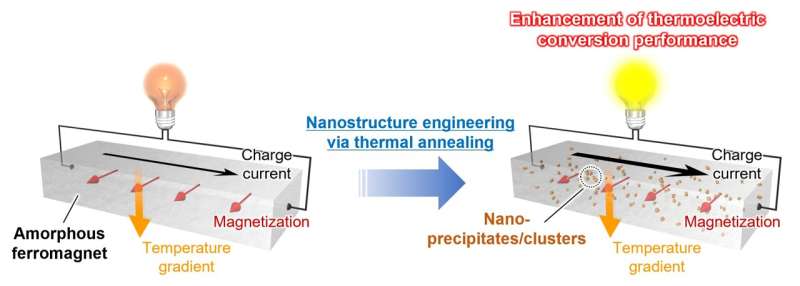

A research team from NIMS and Nagoya University has demonstrated that an iron-based amorphous alloy, widely used as a soft magnetic material in transformers and motors, can be transformed into a "transverse" thermoelectric conversion material that converts electric and thermal currents in orthogonal directions, with just a short period of heat treatment. The study is published online in the journal Nature Communications

This is the first example that highlights the importance of microstructure engineering in the development of transverse thermoelectric conversion materials and provides new design guidelines for materials development to realize environmentally friendly power generation and thermal management technologies using magnetic materials.

The use of transverse thermoelectric effects in magnetic materials is expected to simplify the structure of thermoelectric conversion devices compared to the longitudinal thermoelectric effects, where electric and thermal currents are converted in parallel directions. This simplification can lead to enhanced versatility and durability of the devices, as well as cost reduction

The main focus of the development of magnetic materials for transverse thermoelectric conversion has been the exploration of new alloys based on electronic structure, with no research on the microstructure within the materials.

The team has now demonstrated that a simple three-minute heat treatment of an iron-based amorphous alloy, without changing the average composition of the material, significantly improves the performance of the anomalous Nernst effect—one of the transverse thermoelectric effects.

The anomalous Nernst coefficient, obtained at the optimal heat treatment temperature, showed the highest value known among magnetic amorphous alloys, and the improvement was found to be significantly influenced by nano-sized copper precipitates within the alloy. This result suggests that not only the electronic structure and composition of the material but also the design and control of the microstructure are important for enhancing the anomalous Nernst coefficient.

The developed magnetic material can be easily mass-produced and scaled up, and it is also flexible. By further developing magnetic materials with even higher anomalous Nernst coefficients through microstructure control, the team aims to apply this technology to energy conversions in electronic devices and to thermal sensing technologies.

More information: Ravi Gautam et al, Creation of flexible spin-caloritronic material with giant transverse thermoelectric conversion by nanostructure engineering, Nature Communications (2024). DOI: 10.1038/s41467-024-46475-6

Journal information: Nature Communications

Provided by National Institute for Materials Science