This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Modeling polymers for next-generation manufacturing and sustainability

Polymers are large molecules that are made by linking a series of identical building blocks. They are attractive for manufacturing because they are inexpensive and easy to process and modify.

To expand polymers' applications and improve their sustainability, scientists need a greater understanding of their structural dynamics. These soft materials experience changing conditions during manufacturing. This can affect their final properties and performance. As polymers undergo phase changes (for example, from solid to liquid) the way they react to forces becomes increasingly complex and hard to measure.

In this work, researchers combined theory and computational modeling to characterize melted polymers under steady flow conditions. They found universal features that can aid in the design of advanced polymer materials. The research is published in the journal Physical Review Letters.

Polymers are advancing manufacturing, especially additive manufacturing or 3D printing. Companies can use these low-cost, easily processed soft materials to make many different parts, tools, and products. Advancing polymers could enable industry to efficiently manufacture higher quality products with tailored properties and intricate shapes and structures. This would expand polymers' use in high-performance applications such as automobiles and aerospace.

Researchers have a good understanding of polymer dynamics in an equilibrium state. However, they lack information about how polymers respond to stress and temperature changes during processing. The modeling approach in this study allows researchers to extract this information. This could lead to more accurate predictions of performance and better design of polymer materials.

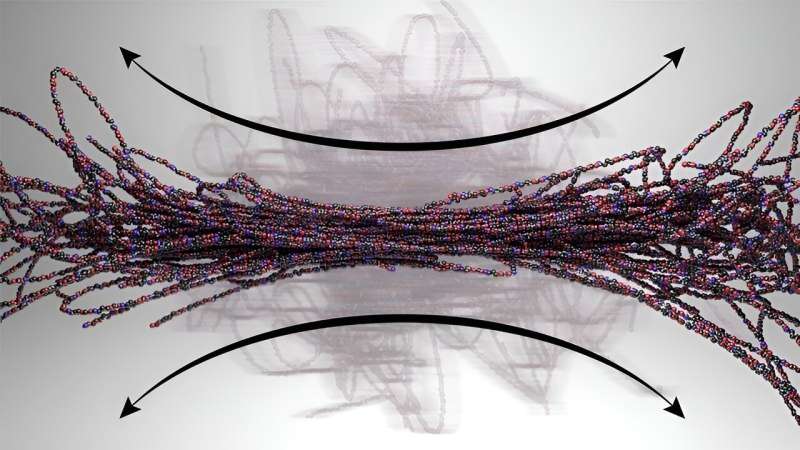

Polymer materials, including plastic and rubber, are made up of long chains of molecules that can be moved around by applying energy, such as changing the temperature or applying an external force. In the bulk polymer material, many of these polymer chains are entangled and interact via randomized motion, or Brownian motion, that can be directly linked to observable properties. Car tires, for example, become more flexible at higher temperatures and more rigid in cold weather.

When polymers are melted, they flow, meaning molecular chains interact with themselves and other molecule chains and are also free to move differently in different directions. Probability theory can characterize polymer physics in an equilibrium state but has not been sufficient to describe polymers under flow that introduce additional mathematical complexity.

In this study, researchers introduced two key methods to "fingerprint" complex polymer flow dynamics. They expanded on Brownian motion with complementary reference frames to address single polymer chain motions relative to flow and used a spherical harmonic expansion technique to resolve anisotropic movement.

More information: Zhiqiang Shen et al, Fingerprinting Brownian Motions of Polymers under Flow, Physical Review Letters (2022). DOI: 10.1103/PhysRevLett.129.057801

Journal information: Physical Review Letters

Provided by US Department of Energy